Home - Search - Browse - Alphabetic Index: 0- 1- 2- 3- 4- 5- 6- 7- 8- 9

A- B- C- D- E- F- G- H- I- J- K- L- M- N- O- P- Q- R- S- T- U- V- W- X- Y- Z

Delta

Delta

Credit: (c) Mark Wade

Status: Active. First Launch: 1960-05-13. Last Launch: 1962-09-18. Number: 12 . Payload: 226 kg (498 lb). Thrust: 68,040.00 kN (15,296,000 lbf). Gross mass: 54,050 kg (119,150 lb). Height: 31.00 m (101.00 ft). Diameter: 2.44 m (8.00 ft). Apogee: 100,000 km (60,000 mi).

The Delta space launch family had its roots in the Thor IRBM. Thor was a 2400 km range missile with essentially the same characteristics as the Army's Jupiter. It was developed by Douglas Aircraft in one of the most accelerated crash programs in history. 'Chief Designer' of the Thor was Jack Bromberg. He was not educated formally as an engineer, but was smart and dynamic. Company owner Donald Douglas had hired him back in the 1930's. He was a major influence in Douglas' winning response to the USAF request for proposal, which emanated from USAF Missile Czar General Bernard Schriever.

The Air Force requirement was to build an IRBM around a discarded rocket motor design. The engine had been developed as the sustainer engine for the Atlas missile when the requirement was to launch a 2700 kg thermonuclear warhead over an intercontinental range. When it became apparent that the warhead could be reduced to less than half that weight, the Atlas was downsized, and the 68 metric ton thrust sustainer motor was no longer required.

Douglas flew a first prototype only thirteen months after go-ahead. Sixty Thors were deployed to missile sites in Great Britain under Project Emily. After a few years the Thors were withdrawn from Britain (and the Jupiters from Turkey) as part of the secret codicil of Kennedy's deal to end the Cuban Missile Crisis. A few continued in an offensive military role as a nuclear-tipped anti-satellite system, based on Johnson Atoll in the Pacific, until the end of the early 1970's. Surplus Thors were used for a variety of suborbital re-entry vehicle tests.

After the Sputnik shock, all available assets were pressed into service. Thor was developed into a workhorse for the space program. The Able stage developed for the Vanguard project was mated to the Thor. A fundamental problem was that the thrust to weight ratio of the basic vehicle left little margin for growth or larger upper stages. This was solved by using Castor solid rockets strapped to the base of the vehicle to increase the lift-off thrust. Almost by accident rather than design, Thor developed into the Delta, the standard American medium-lift launcher, continually evolving through the use of more and larger strap-on boosters, a cylindrical and stretched core, and enlarged upper stages. The original Aerojet Able upper stage evolved into the Delta. From 1959-1972 the US Air Force and NASA flew versions of the launch vehicle using the same core and solid booster technology, but with the Agena upper stage rather than the Delta. After going through a bewildering myriad of military versions it emerged as the standardized, reliable and economical Delta commercial satellite launch vehicle by the mid-1970's. Improved Delta versions continued in production into the next millennium, with nearly 1,000 airframes completed, and the end of production announced yet again in 2008.

The innumerable 'deaths' and resurrections of the Delta are described in Aerojet - The Creative Company, 1995:

Using NASA terminology, their first Delta launch vehicle was basically an Air Force Able consisting of a Thor first stage, an Able second stage, and a solid propellant third stage of nominally 2760 lbf thrust produced by Allegheny Ballistics Laboratory (ABL). These vehicles and their powerplants are discussed above as part of the Able family. The first NASA contracts for these upper stages were in 1959, deliveries began in 1961, and numerous additional contracts followed. Also in 1961, NASA shifted to the Ablestar configuration. The first launch using this configuration occurred on May 13, 1960 and, according to one source on NASA history, did not reach orbit because of a malfunction in the Aerojet stage. Aerojet's findings indicate that it never got the signal to fire. The second attempt on August 12, 1960 was successful, and these engines were used until years later when the more powerful Air Force Delta second stage ablative engines became available.The Delta 3 introduced a new cryogenic upper stage in 1998. However the vehicle began tests just as the satellite market collapsed. It was flown only three times, two of the launches being failures. Meanwhile the most numerous and successful version, the Delta 7000 series, continued in service. The completely new-design Delta 4 was supposed to replace it in service, but the Delta 7000 remained not only lower cost but the most reliable launch vehicle produced in the United States. Nevertheless, in 2008, it was announced that production would be terminated and the Delta 4 would replace it.At this point the Air Force, realizing the need for a larger space launch capability separate from the civilian efforts, selected the concept of using both stages of Titan II with various third and fourth stages, and later an array of zero stages. In very general terms, they retained the Agena for Thor and Atlas upper stages, and sought a new larger and simpler third stage, which was called Transtage. Agena was, however, regularly used on both Thor and Titan lower stages, and was often favored because it was a pump fed unit and was much lighter. The desirability of low chamber pressure, ablative chambers and a pressurized propellant feed system had been demonstrated in Vanguard, Hydra, and Ablestar, which led to the selection (for Titan) of the Transtage configuration using two chambers similar to, but larger than Ablestar. A variation of this became known as the Improved Delta stage, and was used extensively on Thor -so much so that the vehicle became known as Thor/Delta, and in some cases, only as Delta, or later as Thrust Augmented Delta, Long Tank Delta, Delta - PAM, and similar versions.

The resulting (improved) Delta launch vehicle underwent a bewildering succession of changes in configuration and performance (some incremental and some extensive) which is continuing to this day. All three stages have undergone upratings and replacements with more powerful engines, and there has been a succession of increasing numbers and sizes of strap-on solid propellant rocket zero stages. Aerojet's original ablative Delta engine had a radiation cooled nozzle exit section, burned N2O4/Aerozine-50 and produced a vacuum thrust of 9000 lbf. This unit also underwent several modifications, ending up with a thrust of 10,200 lbf, and a variety of tank sizes. A throttling (variable thrust) version was developed for a Navy application, and the Delta family could be generally distinguished from Transtage engines by the fact that the Delta gimbal point was at the head end (above the valve assembly), while the Transtage engines (in addition to being smaller) gimbaled at the plane of the nozzle throat.

In the early 1970s the expendable launch business was going quite well technically, but changes to reduce cost and increase payload were examined continuously. A series of Delta Alternative Studies was made, some being funded by NASA, but mostly in-house. One such study by Aerojet explored the concept of using a single barrel of the LR-87 engine. This would be used to improve Delta performance, but sufficient development funds were not available and the shuttle was receiving all the emphasis, so the idea died. Another of these studies involved the use of liquid boosters in place of the nine solid boosters then attached to the Thor as a zero stage. The concept was to use either storable or LOX/RP-1 single LR-87 thrust chambers, pressure fed from filament wound tanks. The tanks would use thin metal liners to ensure freedom from leakage - as is still required today for high pressure, light weight filament wound vessels. Aerojet's solid rocket division had done some very encouraging work on high performance solid rocket engine chambers of this same type, and the prices were very attractive. The Aerojet team: Wally Dinsmore, Bob Frew, Lynn Meland. Howard Williams, and Chris Harlambakis from our Los Angeles office had many meetings and technical discussions at Huntington Beach. Two were memorable. The first was in October 1987 when their hosts kept slipping out of the meeting to check their stocks - this was the day the stock market fell drastically. No decisions were made that day. The second meeting almost didn't start. When the Aerojet contingent arrived, there was no one in the building because of an earthquake. The meeting finally got going, and just as Wally was to give his punch line cost and schedule estimate, the building shook with a severe aftershock and plaster dust fell from the ceiling. There were no decisions made that day either. This concept, like the others, couldn't get over the hurdle of the initial development cost - and probably the image of starting up a major new booster program.

Some additional insights into the early part of NASA's long succession of changes are provided by Dan Dembrow, who worked for NASA on the Delta Program at Goddard Space Flight Center:

The Delta launch vehicle was always viewed as an interim launch vehicle in NASA's stable, and was used to retain an intermediate size orbital payload capability until larger launch vehicles were developed. The Delta Project Manager at NASA, Bill Schindler, had a knack for keeping the program alive. He would participate in the launch vehicle assignment process, and when he found that Headquarters was about to kill the Delta on the grounds that a new mission exceeded its capabilities, he would assure them that Delta could do the job. Then he would challenge his technical staff, and often with the aid of the prime contractor, McDonnell Douglas, and our Goddard technical staff, to figure out a way to extend the flight envelope. This process occurred many times, and it was extremely difficult as production launch vehicles are not meant to undergo such constant changes in design. Delta payloads grew from about 200 lbm in low earth orbit in 1960 to about 4100 lbm in geosynchronous orbit by 1990.The customary tug-of-war between the overall vehicle contractor and component system supplier over who should supply how much of the product, began as might be expected. As long as the project remained in Azusa, we had been able to keep the costs below anything Douglas could match. However, at the time when it was to be moved to Sacramento, management required the use of the "new" Commitment Proposal Estimating System which resulted in higher estimated costs. Also, the Douglas Huntington Beach plant was extremely low on work. As a final touch, Aerojet solved the problem by arrogantly sticking to the much higher price to our customer (Douglas). They promptly responded by replacing our system with a similar unit from TRW (surplus LM units) that unfortunately had slightly lower performance. Most of the production for NASA in that time period continued with this TRW engine. Douglas also had kept wearing away Aerojet's share of the project so that we went from supplying the complete stage to the present status of supplying only the thrust chamber assembly and propellant feed lines.In the 1960s, Goddard contracted directly for many of the components (including the second stage from Aerojet), and supplied them to McDonnell Douglas as government furnished equipment (GFE). During this period, Schindler oversold what Delta could do, and each successive payload had us in a quandary. Aerojet was always ready to test changes that would increase the second stage total impulse, and did so frequently. In one such case, a special test was required, and Aerojet went to a lot of trouble to upgrade the test stand for display to NASA management. Among the improvements was a new fail-safe system, and they even went to the point of repainting the bay. At the scheduled date the NASA managers had a schedule conflict, so I was the only NASA observer.

The test took place as scheduled, the instrumentation performed flawlessly, the test values were all nominal, and suddenly the test ended unexpectedly in mid-duration. Nothing within the control room showed anything wrong. When we went out into the test bay, the newly painted walls were on fire. The heat from the fire must have damaged some wiring in the fail-safe system, which promptly terminated the firing.

Aerojet did not realize the critical nature of the test, and this failure almost inadvertently killed the Delta program. Fortunately I was the only NASA observer, and a re-test was successfully conducted within a few days, so Schindler by that time was able to persuade NASA management that all was well. The critical decision was made to fly the mission on Delta.

After a painful hiatus, we began work in 1975 on a complete "Fat Delta" stage for the Japanese N-II launch vehicle. At this point we received Air Force funding for performance improvement, one element of which was called the Delta I.T.I.P. (Improved Transtage Injector Program), and used an improved curved face, baffled injector. A still higher performance unit was developed, using a flat faced, baffled injector, and these were used in a two barrel configuration for a classified program. Their excellent performance made this chamber configuration popular, and was the basis for a long but relatively modest rate.

The configuration of Delta vehicles was encoded for forty years as follows:

- First digit: basic vehicle configuration:

This was defined up to 2004 as follows:

- 0 = Castor 2 solid propellant strap-ons, Long Tank Thor core with MB-3 engine

- 1 = Castor 2 strap-ons, Extended Long Tank core with MB-3 engine

- 2 = Castor 2 strap-ons, Extended Long Tank core with RS-27 engine (derived from surplus H-1 engines of the Saturn IB).

- 3 = Castor 4 solid propellant strap-ons, Extended Long Tank core with RS-27 engine

- 4 = Castor 4A strap-ons, Extended Long Tank core with MB-3 engine

- 5 = Castor 4A strap-ons, Extended Long Tank core with RS-27 engine

- 6 = Castor 4A strap-ons, Extra Extended Long Tank core with RS-27 engine

- 7 = GEM-40 solid propellant strap-ons, Extra Extended Long Tank core with RS-27A engine

- 8 = GEM-46 solid propellant strap-ons, Delta-3 strengthened Extra Extended Long Tank core with RS-27A engine

- 9 = GEM-60 solid propellant strap-ons, Delta-4 Lox/LH2 cryogenic core with RS-68 engine.

After 2004 this was revised to:

- 2 = Delta II first stage (previously Delta 6000 and 7000 series)

- 3 = Delta III first stage (previously Delta 8000 series)

- 4 = Delta IV first stage (previously Delta 9000 series)

- Second digit: Number of solid propellant strap-ons (0, 3, or 9 prior to Delta IV. 0, 2, or 4 for Delta-4).

- Third digit: Second stage

- 0 = Delta storable propellant stage with AJ10-118 series engines

- 1 = Delta storable propellant stage with TR-201 engines (surplus TRW Apollo Lunar Module upper stage engines)

- 2 = Delta K storable propellant stage with AJ10-118K engine

- 3 = Delta-3 Lox/LH2 cryogenic upper stage with RL10B-2 engine

- 4 = Delta-4 Lox/LH2 cryogenic upper stage with 4 m diameter

- 5 = Delta-4 Lox/LH2 cryogenic upper stage with 5 m diameter

- Fourth digit: Third stage

- 0 = No third stage

- 1 = Not used

- 2 = Not used

- 3 = Star 37D / TE-364-3 solid propellant kick stage

- 4 = Star 37E / TE-364-4 solid propellant kick stage

- 5 = Star-48B / PAM-D solid propellant kick stage (often listed as '0' upper stage with a PAM-D due to the modular nature of the PAM configuration).

- 6 = Star 37FM solid propellant kick stage

- Optional letter after fourth character: An 'H' here indicated a 'Heavy' configuration. For Delta II, this was use of 46 inch diameter GEM solid strap-on motors in place of the standard Castor motors. For Delta IV, it indicated use of two strap-on Common Booster Cores (CBC) to supplement the CBC on the core stage.

- Dash number: Payload fairing. For Delta II, this indicates the diameter of the fairing in feet. For Delta III or Delta IV, it indicates the length of the fairing in meters.

Stage Data - Delta

- Stage 1. 1 x Thor DM-19. Gross Mass: 49,340 kg (108,770 lb). Empty Mass: 3,125 kg (6,889 lb). Thrust (vac): 758.711 kN (170,565 lbf). Isp: 282 sec. Burn time: 165 sec. Isp(sl): 248 sec. Diameter: 2.44 m (8.00 ft). Span: 2.44 m (8.00 ft). Length: 18.42 m (60.43 ft). Propellants: Lox/Kerosene. No Engines: 1. Engine: LR-79-7. Status: Out of Production.

- Stage 2. 1 x Delta 104. Gross Mass: 4,472 kg (9,859 lb). Empty Mass: 590 kg (1,300 lb). Thrust (vac): 35.098 kN (7,890 lbf). Isp: 278 sec. Burn time: 296 sec. Diameter: 1.40 m (4.50 ft). Span: 1.40 m (4.50 ft). Length: 5.88 m (19.29 ft). Propellants: Nitric acid/UDMH. No Engines: 1. Engine: AJ10-104. Status: Out of Production.

- Stage 3. 1 x Altair 1. Gross Mass: 238 kg (524 lb). Empty Mass: 30 kg (66 lb). Thrust (vac): 12.450 kN (2,799 lbf). Isp: 256 sec. Burn time: 38 sec. Isp(sl): 233 sec. Diameter: 0.46 m (1.50 ft). Span: 0.46 m (1.50 ft). Length: 1.83 m (6.00 ft). Propellants: Solid. No Engines: 1. Engine: X-248. Status: Out of Production.

More at: Delta.

| Able Nitric acid/UDMH propellant rocket stage. Engine for Vanguard was AJ10-37; for later Able models AJ10-41 and AJ10-42. Total of 21 stages built and delivered by Aerojet. |

| Delta 104 Nitric acid/UDMH propellant rocket stage. . |

| Delta A Nitric acid/UDMH propellant rocket stage. Able was only the first of many engine and application programs that flowed from the Vanguard experience base. These included Able, Ablestar, Delta, Fat Delta, the Japanese N II, and applications or offshoots such as Hydra, Saint (Satellite Intercept), and other classified programs. |

| Delta D American orbital launch vehicle. Unaugmented Thor with Delta and solid propellant upper stages. |

| Delta E American orbital launch vehicle. Unaugmented Thor with Delta and solid propellant upper stages. |

| Delta F Nitric acid/UDMH propellant rocket stage. . |

| Delta P N2O4/Aerozine-50 propellant rocket stage. . |

| Able-Star Nitric acid/UDMH propellant rocket stage. The Air Force requested increases in the propulsion system capabilities of the original Able upper stage design in an effort to meet their ever-expanding mission requirements. As a result, the stainless steel version of the basic Able engine was selected, and it was uprated to increase thrust 34.7 kN to 37.0 kN and to increase the duration 2-1/2 times (easily done with the stainless steel thrust chamber) - and this configuration was called Ablestar. |

| Delta K N2O4/Aerozine-50 propellant rocket stage. . |

Family: orbital launch vehicle. Country: USA. Engines: LR79-7, AJ10-104. Spacecraft: Pioneer 0-1-2, KH-1, S-2, Transit, Midas, Pioneer 5, TIROS, GRAB, Echo, Courier, KH-2, KH-5, Lofti, P-14, Injun, EPE, KH-3, TRAAC, Oscar, Lofti 2, SECOR, SURCAL, Ferret, KH-4, OSO, Ariel, Anna, Telstar, ERS, Alouette, TAVE, Starfish, NRL ELINT, Relay, Syncom, KH-6, P 11, SSF, AE, RADOSE, KH-4A, LAMPO, Asset, APL satellite, IMP, GGSE, AFP-43, Echo 2, BE, Program 437, Starflash, Nimbus, OGO, Calsphere, DMSP Block 4A, DODECAPOLE, Intelsat 1, Tempsat, GEOS, DME, Pioneer 6-7-8-9-E, Pageos, TOS, Intelsat 2, Biosatellite, Timation, Aurora, KH-4B, TTS, RAE, Intelsat 3, HEOS, Program 922, Isis, PAC, TETR, SOICAL, NATO 1, ITOS, SERT, DMSP Block 5A, TOPO, CEPE, SESP, DMSP Block 5B, ASTEX, NOSS, TD-1A, Landsat 1-2-3, HS 333, Skynet, SMS, DMSP Block 5C, Intasat, Symphonie, COS, Spacebus 100, ETS, GOES, AS 1000, CTS, Marisat, JISS, NATO 3, LAGEOS, DMSP Block 5D, ESA-Geos, Himawari, Sirio, ECS/OTS, ISEE, Meteosat, CS-1, IUE, PIX, Yuri, CAMEO, Anik satellite, SCATHA, Ayame, SMM, HS 376, Insat 1, Dynamics Explorer, SME, SSTL-70, AS 3000, Landsat 4-5, IRAS, CS-2, Advanced Tiros N, Exosat, AMPTE, ASC, EGS, MABES, SDI, Marine Observation Satellite, CS-3, GPS Block 2 and 2A, COBE, HS 601, Debut, LACE, RME, ROSAT, Eurostar 1000, Losat, JERS, EUVE, DUVE, Geotail, SEDS, PMG, Wind, Radarsat, SURFSAT-1, XTE, NEAR, Polar, MSX, Mars Global Surveyor, Mars Pathfinder, GPS Block 2R, LM 700, ACE, Globalstar, Deep Space 1, SEDSAT, MCO, Mars Polar Lander, Stardust, ARGOS, Orsted, Sunsat, Landsat 7, FUSE, IMAGE, EO-1, Munin, SAC-C, Mars Odyssey, GeoLITE, MAP, QuickBird, Jason, TIMED, Aqua, Contour, CHIPSat, ICESat, XSS, MER, SIRTF, Gravity Probe-B, Aura, Messenger, Swift, Deep Impact, Calipso, Cloudsat, Mitex, Stereo, USA 193, Cosmo-SkyMed, Phoenix, WorldView, Dawn, GLAST. Stages: Altair 1. Agency: Douglas. Bibliography: 126, 140, 17, 172, 18, 2, 276, 277, 279, 281, 296, 297, 34, 4, 405, 42, 45, 480, 498, 5, 552, 554, 6, 61, 88.

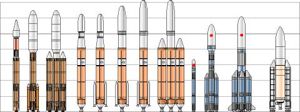

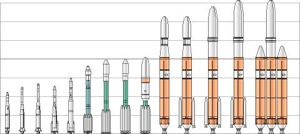

| New Generation LVs From left: 3 versions of Atlas 5, 5 versions of Delta 4, 3 versions of Chinese NGLV, Ariane 5. Vertical scale is 10 m intervals. Credit: © Mark Wade |

| 392nd Thor Squadron Vandenberg 392nd Squadron Thor launch personnel, Vandenberg, 1962 or 1963. Credit: Larry Rhoads |

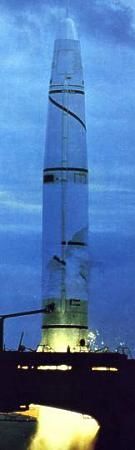

| Thor Credit: via Andreas Parsch |

| Thor Burner 2A Thor Burner 2A - COSPAR 1975-043 |

| Thor Burner Thor-Burner 2 - COSPAR 1967-065 |

| Thor Burner 2 Credit: US Air Force |

| Thor Burner Thor Burner - COSPAR 1965-003 |

| Thor Burner 3 Credit: US Air Force |

| Thor Blockhouse Inside view of the Thor Burner I program block house looking at the launch control consoles (ca 1965). Credit: Larry Rhoads |

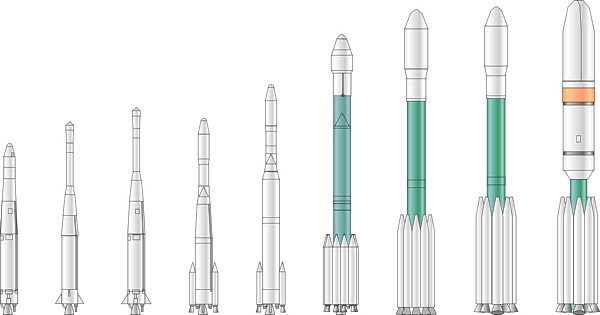

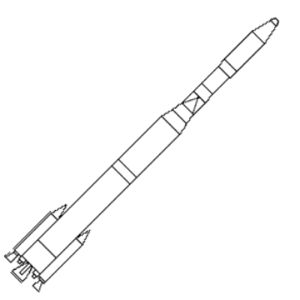

| Delta LV Family From left: Thor-Delta, Delta A, Delta B, Delta E, Delta M, Delta 2000, Delta 6000, Delta 7000 Heavy, Delta 3, Delta IV, Delta Heavy. Credit: © Mark Wade |

| Thor Able 2 Credit: © Thomas Kladiva - Thomas Kladiva |

| Thor Able Star Credit: © Mark Wade |

| Thor-Able Credit: US Air Force |

| Launch Complex 17B Launch Complex 17B - Cape Canaveral |

| Thor Able Thor Able - COSPAR 1959-004 |

| Thor Able Thor Able-Star - COSPAR 1960-013 |

| Thor Able Thor Able - 58 |

| Thor Able Credit: © Mark Wade |

| Thor Agena A Thor Agena A - COSPAR 1960-M |

| Thor Agena A Credit: © Mark Wade |

| Agena A Stage Credit: © Mark Wade |

| TA Thor Agena B TA Thor Agena B - COSPAR 1963-027 |

| Thor Agena B Thor Agena B - 1962 |

| Thor Agena B Thor Agena B - COSPAR 1964-052 |

| Thor TAT/Agena Thor Augmented Thrust / Agena Credit: US Air Force |

| TA Thor Agena D TA Thor Agena D -1963-02-28 |

| TA Thor Agena D TA Thor Agena D - COSPAR 1967-029 |

| TA Thor Agena D TA Thor Agena D - COSPAR 1964-061 |

| TA Thor Agena D TA Thor Agena D - COSPAR 1963-034 |

| TA Thor Agena D TA Thor Agena D - COSPAR 1964-001 |

| Thorad Agena D SLV-2 Credit: via Andreas Parsch |

| LT Thor Agena D LT Thor Agena D - COSPAR 1966-102 |

| Delta D Credit: © Mark Wade |

| Delta E1 no. 44 Delta E1 no. 44 - COSPAR 1967-001 |

| Delta M6 no. 83 Delta M6 no. 83 - COSPAR 1971-019 |

| Delta M no. 80 Delta M no. 80 - COSPAR 1970-062 |

| N1 Japan Credit: © Thomas Kladiva - Thomas Kladiva |

| Delta 100 Credit: © Mark Wade |

| Delta 1900 no. 99 Delta 1900 no. 99 - COSPAR 1973-101 |

| Delta 3910 no. 151 Delta 3910 no. 151 - COSPAR 1980-014 |

| Delta 3925 Credit: Boeing |

| Delta 7925 Credit: Boeing |

| Delta LV Delta LV Solid Motor Separation Credit: Boeing |

| Delta 2 liftoff Credit: NASA |

| Delta 2 Credit: © Mark Wade |

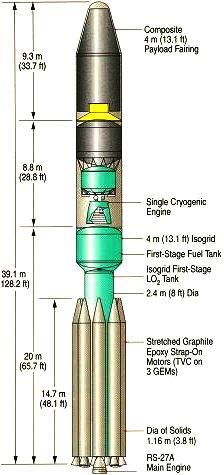

| Delta 3 Cutaway Delta 3 Cutaway Drawing Credit: Boeing |

| Delta 3 Delta 3 on the pad before its first launch attempt. Credit: Boeing |

Back to top of page

Home - Search - Browse - Alphabetic Index: 0- 1- 2- 3- 4- 5- 6- 7- 8- 9

A- B- C- D- E- F- G- H- I- J- K- L- M- N- O- P- Q- R- S- T- U- V- W- X- Y- Z

© 1997-2019 Mark Wade - Contact

© / Conditions for Use