Home - Search - Browse - Alphabetic Index: 0- 1- 2- 3- 4- 5- 6- 7- 8- 9

A- B- C- D- E- F- G- H- I- J- K- L- M- N- O- P- Q- R- S- T- U- V- W- X- Y- Z

Solid

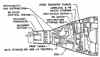

Solid Propellant Isp

Credit: Aerojet

The disadvantages of solid propellants in space applications include:

- Slightly higher empty mass for the rocket stage

- Slightly lower performance than storable liquid propellants

- Transportability issues: Solid propellants are cast into the motor in the factory, unlike liquid fuel rockets which can be fuelled at the launch pad. This means they have to either be: 1) limited in size to be transportable (as for the Delta and Ariane strap-on motors); 2) cast in segments, with the segments assembled at the launch base (as for Titan and the Space Shuttle); or 3) cast in a factory near the launch site (actually done for large test motors intended for Saturn V upgrades).

- Once ignited, they cannot be easily shut down or throttled. Thereafter they have to be pre-cast or milled out for a specific mission.

- Often catastrophic results in the event of a failure

Advantages of solid rocket motors, many of which make them ideal for military applications:

- High density and low volume

- Nearly indefinite storage life

- Instant ignition without fuelling operations

- High reliability

Brief History of Solid Propellant Development

Solid propellant rockets, using black powder as the propellant, were introduced by the Chinese in the early 13th century. The next significant event occurred in the late 17th and 18th centuries when the development of nitro-cellulose, nitroglycerine, cordite, and dynamite resulted in their consideration as a rocket propellant. Immediately before World War I, the French used nitro-cellulose as a propellant for artillery rockets.

In 1936, Dr. Theodore von Karman, and his associates at Caltech began a program that resulted in the first composite propellants using an organic matrix (asphalt) and an inorganic oxidizer (potassium perchlorate). Their work also covered the beginnings of understanding the associated interior ballistics, combustion, ignition, and related structural-materials issues. This was the start of modern solid propellant rocketry. Composite propellants virtually replaced double base propellants (based on mixtures of nitro-cellulose and nitroglycerine) in most applications.

Following World War II many companies and agencies began propellant development programs involving a wide variety of oxidizers, fuels (binders) and processing methods. In this era, improvements in performance (quantified as specific impulse) were largely achieved by increasing oxidizer loading. Most of the binders were supplied by the rapidly expanding plastics industry.

The ever increasing number of potential missile programs resulted in growing pressure to provide other propellants that had improvements in terms of: performance, structural properties (strength, stability, impact resistance) thermal characteristics (temperature range, cycling), processing, cost, safety, quality, and reliability. In the early 1950s, Atlantic Research invented the use of up to 15 percent powdered aluminum to replace a like amount of oxidizer - giving a performance gain of about 15 percent. Propellant researchers began to understand the complete chemistry of solid propellants, and the need for molecular chain extensions and cross linking of the binders became apparent. The invention of bonding agents (as part of the fuel) greatly improved not only the mechanical properties, but also the resistance to ageing, humidity, and temperature cycling.

Two mainstream composite propellant-binder families emerged (Polyurethane and Polybutadiene), but these were accompanied by a large number of variations and evolutionary products. In addition, there were numerous associated-alternative formulations and concepts tailored to specific missile program requirements. Included among them were: Nitro-polymers, Fluorine based propellants, Beryllium additives, etc. At the same time double base propellants (based on mixtures of nitro-cellulose and nitroglycerine) continued to evolve and compete. When double base propellants were used to replace conventional binders this resulted in the highest values of specific impulse ever attained.

Aerojet initially concentrated on Polyurethane (PU), and Thiokol favored Polybutadiene (PB). Thiokol's work included PBAA, a copolymer of Butadiene and Acrylic Acid. This was replaced by PBAN, a terpolymer including Acrylic Acid and Acrylonitrile. Aerojet also conducted considerable development effort in this area, and PBAN was used in Aerojet's 260-inch space booster.

Several other companies also worked in these and other related areas. For example Phillips Petroleum with Rocketdyne developed Carboxyl Terminated Polybutadiene (CTPB) using both a Lithium initiated polymerization, and a free radical type. These propellants were widely used, but were later overtaken by Hydroxyl Terminated Butadiene (HTBD). By the 1990's Aerojet favored HTBD and formulations thereof including double base binders.

In addition to the binder evolution, there was a variety of oxidizers to choose from: ammonium and potassium nitrates, perchlorates, and picrates. Perchlorates were generally favored, but later environmental concerns were expressed at the amount of chlorine compounds (mainly hydrochloric acid) emitted into the atmosphere. One possible solution was the use of a hybrid (liquid and solid) system with a PBAN or similar grain and liquid oxygen as the oxidizer. This also provided a substantial cost saving, and allowed thrust variation and control features that were otherwise not easily achieved.

Paralleling the propellant formulation was development in the design of the propellant grain shape. In most asphalt rockets, the propellant was simply cast into the cylindrical motor chambers (or in some cases into a thin metal jacket which was then inserted into the chamber). Burning occurred only on the exposed aft end of the propellant, resulting in a constant level of thrust. The Aeroplex and other free-standing, rigid cylindrical grains (burning on the inner diameter and outer diameter.) also produced a constant thrust-time curve, because the increase in internal burning surface area just matched the decreasing external surface area.

Case-bonded propellants called for a different configuration of the burning surface. The outside of the propellant was bonded to the chamber and protected it from the hot gases. A simple cylindrical perforation down the center of the grain would produce a steadily increasing pressure and thrust from very low at start to very high at completion of burning. The solution was to use a central star shaped perforation, which could produce an essentially flat thrust-time curve. The perforation was accomplished by casting the propellant around a core of the desired shape, which was removed after the propellant was completely cured. The tapered rays of the star provided an initial large burning surface, which decreased as the points burned away. Variations in the core geometry allowed a wide range of thrust-time characteristics, to match overall missile requirements.

Additional variations could be achieved by longitudinal variations in the core size and shape, as well as by casting layers of propellant having different characteristics. This latter concept was used for many tactical missiles requiring a boost-sustain thrust curve. For years, grain design was performed by manual geometric manipulation, but computer aided design greatly simplified the task.

The earliest production process for asphalt propellant was actually to hand-stir the ground oxidizer into the heated asphalt. Quality control and consistency were highly questionable, and the safety aspects were in hindsight, terrifying. The immediate solution was to use commercial bread dough mixers in steadily increasing size and robustness. For the more viscous propellant families, much more sturdy mixers were adapted from the tire industry. In addition, the commercially available oxidizers required grinding to achieve the desired fine grain sizes and grain size distribution.

Following fatal accidents in both propellant mixing (asphalt) and oxidizer grinding (potassium perchlorate), production processes were improved to include remote operation, modern instrumentation and control, and a host of other subsystems which significantly improved safety, versatility, and consistency.

Progressive Development of Large Solid Rocket Motors

In the United States:

- Early 1950's: Hermes- Sergeant (Army): 32 inch

- March 1956: Polaris (Navy): 54 inch

- Late 1950's: Minuteman (Air Force): 65 inch (Thiokol)

- 1960-1963: USAF space development program - 86, 96, 100, 120 inch test motors

- Early 1960's: Titan 3 (DoD-NASA) - 120 inch (UTC)

- 1963-1965: Moon program (DoD-NASA) for Nova-Saturn vehicles

- 44 inch (Aerojet), 65 (Thiokol), 120 inch (Aerojet) subscale motors

- 156 inch (Lockheed and Thiokol), 260 inch (Thiokol and Aerojet) PBAN full scale motors.

- Early 1970's: Shuttle - 146 inch PBAN

- 1990's: Titan 4B USRM - 126 inch HTPB

Black Powder Rockets

Solid propellants of the composite type contain separate fuel (or reducer, chemically) and oxidizer (in a separate compound) intimately mixed. While generally not considered as composite, black powder was in fact the oldest composite propellant. Before 1940 black powder, in common use, was nearly synonymous with the words 'rocket motor'.

Black powder technically should not be called gunpowder because its use in rockets preceded that in guns. The ingredients are charcoal, sulfur, and saltpeter (potassium nitrate). These three ingredients were known in China for many centuries, however, before they were combined into black powder. Charcoal was known from the earliest times, and sulfur and saltpeter at least since the sixth century AD, and probably as far back as the first century BC That the saltpeter is definitely of Chinese origin is indicated by the names given to this material by the Arabs, who called it "Chinese snow", and the Persians, who called it "salt from China".

By 1045, just twenty-one years before William the Conqueror invaded Saxon England, the Chinese were well acquainted with black powder. The Wu-ching Tsung-yao (Complete Compendium of Military Classics) published that year, contained many references to the subject.

In black powder, saltpeter (potassium nitrate- KNO3) is the oxidizer, while sulfur (S), and charcoal (mainly carbon- C) are the fuel. But, depending on the percentage of each ingredient, sulfur may also act as an oxidizer for potassium in the reaction: 2KNO3 + S + 3C = K2S + N2 + 3CO2.

Some early black powder formulae:

- Saltpeter + sulfur + acacia seeds.

- 1 chin 14 ounces of sulfur, together with 2 1/2 chin of saltpeter, 5 ounces of charcoal, 2 1/2 ounces of pitch, and 2 1/2 ounces of dried varnish are powdered and mixed. Next, 2 ounces of dried plant material, 5 ounces of tung oil, and 2 1/2 ounces of wax are also mixed to form a paste. Then these ingredients are all mixed together, and slowly stirred, The mixture is then wrapped in a parcel with five layers of paper, which is fastened with hempen thread, and some melted pitch and wax and is put on the surface.

It was in the early thirteenth century that man turned toy fireworks into weapons of war. The first recorded use of rockets as military weapons was in defense of Kai Fung Fu, China, in 1232. The Chinese "arrows of fire" were fired from a sort of crude rack-type launcher. The black powder was packed in a closed tube (probably bamboo) that had a hole in one end for the escaping hot gases, and a long stick as an elementary guidance (or stabilization) system.

Black powder had a very low specific impulse. About 1280 AD, Arab military men, referring to the propulsive ability of black powder, suggested improvements over the simple Chinese skyrocket. One interesting innovation was what might be best described as an air squid or travelling land mine; it could scurry across land in the manner of a squid through water.

By about 1400 when rocketry became of commercial importance throughout Europe and especially in Italy- where perhaps the greatest designers of pyrotechnics were found. The use of fireworks for all sorts of celebrations created a major market for the manufacture of large quantities of rockets. This spread throughout Europe and reached its zenith during the middle of the eighteenth century.

One of the earliest technical publication on rocketry, the Treatise Upon Several Kinds of War-Fireworks, appeared in France in 1561. The treatise made a critical analysis of the rockets used in earlier military campaigns. A recommendation was made to substitute varnished leather cases for the commonly accepted paper and bamboo ones. There is no evidence that this suggestion was followed by later rocketeers.

Refinements in rocket design came faster over the next few hundred years, at least on paper. In 1591, some three hundred years before Goddard, a Belgian, Jean Beavie, described and sketched the important idea of multistage rockets. Multistaging, placing two or more pockets in line and firing them in step fashion, is the practical answer to the problem of escaping earth's gravitational attraction. An even earlier forerunner was Conrad Haas, chief of the artillery arsenal in Sibiu, Romania, between 1529 and 1569.

By 1600, rockets were being used in various parts of Europe against cavalry, foreshadowing the modern antitank hand weapon, the bazooka of World War II and Korean fame. Later, in 1630, a paper was written describing exploding aerial rockets which created an effect similar to that of the twentieth-century shrapnel shell. By 1688, rockets weighing over 120 pounds had been built and fired with success in Germany. These German rockets, carrying 16- pound warheads, used wooden powder cases reinforced with linen.

Toward the end of the eighteenth century a London lawyer, Sir William Congreve, became fascinated by the challenge of improving rockets. He made extensive experimentation with propellants and case design. His systematic approach to the problem resulted in improved range, guidance (stabilization), and incendiary capabilities. The British armed forces used Congreve's new rockets to great advantage during the Napoleonic Wars.

When Congreve died in 1828, his applied engineering and dedication had already resulted in several technological advances. In addition to fortified cases, new propellants, and incendiaries, Congreve developed stabilizing fins that provided rocketeer with effective stabilised rockets. Congreve rockets were built in weights of 18, 24, 32, 42, 100, and 300 pounds (8, 11, 15, 19, 45, and 136 kg).

In 1906, Alfred Maul successfully took aerial photographs by attaching a camera to a black powder rocket (thereby creating the first instrumented sounding rocket).

During World War I, Le Prieur black powder rockets were sometimes fired from French and British biplanes or from the ground against German captive balloons. Otherwise, military rockets could not compete in range or accuracy with artillery of the day.

In United States, beginning in 1915, many tests were conducted, by Goddard, with rockets using black powder.

In early June 1927, rocket and space enthusiasts in Germany founded the Verein fuer Raumschiffahrt (Society for Space Travel). Some members experimented with black powder rockets.

Automobile manufacturer Fritz von Opel piloted his own rocket glider, Opel Rak.2, in tests near Frankfurt on 30 September 1928. Its 16 rockets, each producing 50 pounds of thrust, were build by Friedrich Sander a pyrotechnics specialist. The propulsion system combining high-thrust, fast-burning powder rockets for initial acceleration with lower-thrust, slower-burning rockets to sustain velocity.

Opel approached Alexander M. Lippisch, a young designer working at the Rhon-Rossitten-Gesellschaft, who had already displayed a penchant for the unorthodox in airplane configuration, with the proposal that he, too, design a glider for rocket power.

Max Valier and Alexander Sander also succeeded in arousing enthusiasm for rocket propulsion in a twenty- seven-year-old aircraft designer, Gottlop Espenlaub. His E 15 tail-less design was of interest as a rocketplane.

On 11 June, Fritz Stamer effected the first rocket- propelled flight in Lippisch's glider. The glider had been dubbed Ente, or Duck. That lead later to the Lippisch's Komet - the Messerschmitt Me 163, liquid rocket manned interceptor.

Reinhold Tiling launched a black-powder rocket from Osnabruck in 1931. It rose to a height of 2.5 miles.

Gerhard Zucker envisioned rocket mail service across the English Channel. The longest shot he attempted was from Harris to Scarp, in western Scotland, on 31 July 1934. But the rocket blew up before takeoff.

In 1939 researchers at the California Institute of Technology in California, seeking to develop a high performance solid rocket motor to assist aircraft takeoff, combined black powder with common road asphalt to produce the first true composite motor. This was the birth of the true composite motor and marked the end of the use of black powder in major rocketry applications.

Double-base solid propellant

Double-base solid propellants consist mainly of fibrous nitro-cellulose and a gelatinizer, or plasticizer, such as nitroglycerine or a similar compound (ethylene glycol dinitrate), each containing oxygen and fuel in the same compound. The term double-base originated from the application of these mixtures as gun propellants. They contained two active constituents, and this name distinguished them from the "single base" smokeless powders which utilized either nitro-cellulose (gun cotton) or nitroglycerine singly as the active constituent.

The first double-base propellant was made by Alfred Nobel in 1888, and was used as a smokeless powder. In such propellants, a high nitroglycerine content tends to increase the energy and burning rate; a high nitro-cellulose content helps to impart a strength to the propellant. The first experiments with double-base smokeless powders as rocket propellant seem to have been made by Goddard in 1918 and by F W Sander in Germany around 1935. The results did not appear to be very promising.

Walter Dornberger, Chief of German rocketry reported: "In 1930.... I got the order to make military weapons out of solid rockets, using, if possible, smokeless powder. This was to be accomplished in military facilities... These solid rocket weapons were ready for mass production as early as 1934".

In Russia, N I Tikhomirov and I P Grave independently proposed to use smokeless powder in rockets before World War I, but these proposals received no official support. After 1917 the attitude changed sharply. Even during the Civil War, engineers N I Tikhomirov and V A Artemev started work on the design of smokeless powder rocket and in 1921 a special laboratory was set up for these studies in Moscow. They became convinced of the necessity of creating a special, slow-burning rocket powder. In 1924, O.G. Filipov and S.A. Serikov, pyrotechnic specialists working at the Artillery Academy then located in Leningrad, developed a formula for a new type of powder based on a non-volatile solvent: 76.5% by weight of nitro-cellulose, 23% TNT, and 0.5% centralite to retard burning. It was called "PTP", i.e. Pyroxyline TNT Powder. By 1928-29, the work conducted in the Artillery Academy permitted development of a semi-production technique for preparing the PTP. A rocket was designed using these solid charges and it was successfully tested on March 3, 1928. In 1929 the basic 24mm solid charges made from PTP, which were prepared in the laboratory shops in great quantities, were selected as the standard in Gas Dynamics Laboratory, the new formed GDL. Therefore, on this standard engineers developed three basic sizes of scaled-up rocket chambers of 68, 82, and 132mm caliber. The latter two subsequently became the basic caliber of Soviet rockets for decades: the RS-82 and the RS-132, later named "Katyusha". An 82mm Jet-Assisted Takeoff rocket was flight tested on the Y-1 and TB-1 aircraft in 1932-33.

In the USSR after World War II, 0.5 ton, 300-400mm rocket motor charges of double-base ballistite were produced for various rockets and missiles. In 1959 the NII-125 (now NPO Soyuz of Liouberetsky) suggested to build ballistite charges of 4 to 5 tons, 1 meter in diameter and 5 to 6 meters long. Korolev then begin to study the RT-1/8K95 predecessor of the RT-2/8K98 ICBM (alias SS-13 Savage) with 4 X 800mm charges of ballistite as the first stage. The fiberglass cluster produced 100 tons of thrust for 30 seconds. But flight tests of the RT-1 from April 1962 to June 1963 at Kapustin Yar were not very successful. The project was cancelled.

In Great Britain, in December 1934 Alvyn Douglas Crow, Director of Ballistic Research at the Woolwich Royal Arsenal, proposed to Sir Hugh Elles, Master of General Ordnance, that the British begin to investigate the possibilities of developing rocket weapons powered by smokeless cordite powder of the unrestricted burning type. Work began in May 1935 and by the summer of 1936 encouraging advances in technique had been achieved. Ultimately Crow headed Britain' wartime rocket program.

In the United States, Parsons and Forman of GALCIT (Guggenheim Aeronautical Laboratory, California Institute of Technology) in 1938 built and tested a smokeless powder constant-volume combustion motor similar to the one that had been used by Goddard. They concluded after these tests that the mechanical complications of constructing an engine using successive impulses to obtain thrust duration of over 10 seconds was impractical. During 1939 and 1940, various mixtures of smokeless powder with black powder (the first double-base/composite propellant) were tested. Most of the tests ended in an explosion. There were those who were convinced that the combustion process of a restricted burning charge in a rocket motor was basically unstable.

In 1917-1918, while studying for his master's degree under A.G. Webster at Clark University, Clarence N. Hickman had met Goddard. Acting upon the suggestion of L.T.E. Thompson, Webster's assistant, Goddard sought Hickman's aid in solving some mechanical problems, with the result that the two worked together during World War I in California, and later at the Aberdeen Proving Ground in Maryland (where Goddard developed a prototype of the Bazooka). After the war Goddard, Thompson, and Hickman continued their association (1920-23). During World War II, the United States rocket program was under the direction of Division A (later 3) of the National Defense Research Committee, a coordinating agency established by President Franklin D. Roosevelt on 27 June 1940. By that time, Thompson was in charge of research at the Navy's Dahlgren Proving Ground, so it was rather easily arranged for Hickman's Section H to begin its testing program at that Virginia site (Section H was named for Hickman, who's letter urging a rocket development program had been instrumental in it being approved).

Because of it very little experience in high-energy solid (double-base) propellants of the type needed for extended-range, high-speed weapons, the United States drew on British rocket knowledge. Within a few years, suitable solid propellants were being produced at the Army's Radford Ordnance Works, the Navy's Indian Head Powder Factory, and the Sunflower Ordnance Works, operated by the Hercules Powder Company. Later, the Section H group moved to the Allegheny Ballistics Laboratory at nearby Pinto, West Virginia, where they worked closely with Army Ordnance, the Chemical Warfare Service, and the Air Corps. Various double-base rockets were produced during World War II including bazooka rockets, 4.5 inch, 5 inch, and 7.2 inch rockets, and the large air-launched Tiny Tim. The Tiny Tim was 11.75 inches in diameter and was later utilized as the booster for the Wac Corporal research rocket (ancestor of Aerobee and Corporal, the first big all-American liquid rocket, guided ballistic missile).

After World War II, Hercules Powder and Allegheny Ballistics Laboratory began the development of a more powerful double-base rocket. On August 20, 1947, the JATO X-201, the first 16 inch. solid-propellant booster, was flight-tested at the Naval Ordnance Test Station, Inyokern, California. The X-201 was used as well in the Naval Ordnance Bureau's Bumblebee program. The cast-double-base propellant booster, later designated the 3DS47000, was developed by Hercules Powder Company. It contained 740 lb. of propellant and delivered a thrust of about 50,000 lb. for 3 sec. It was the forerunner of an entire family of related propulsion units that served as boosters for the Nike, Terrier, Talos, and Honest John missiles.

The Bumblebee program lead directly to the Navy's Terrier and Talos missiles as follow-ons of the Lark anti-aircraft research missile. The Army's Nike-Ajax was a kind of large, guided Wac Corporal, using the same propulsion formula, but with a Bell liquid pressure feed rocket main engine. Bell later developed the pump feed rocket engine XLR65-BA-1 for the X-9 Shrike, predecessor of the Rascal air-to-ground missile. Yet another derivative was a simpler engine for a rocket-propelled pod for the B-58 Hustler bomber. The rocket pod was cancelled, but the Hustler became the basic Agena engine used on upper stages of the Thor, Atlas and Titan boosters. Bell was later involved in the ascent engine development for the Apollo lunar module.

Talos and Honest John motors were used on the big three and four stage Black Brant XI and XII NASA sounding rockets with composite upper stages. The Honest John motor was know as Taurus when used on sounding rockets.

Major later Hercules developments included the Vanguard satellite launcher third stage in the mid-1950's. Hercules developed composite/double-base high energy propellants for Minuteman, Polaris and Poseidon upper stages. (the propellant of Minuteman I third stage consisted of nitro-cellulose + nitroglycerine + triacetin + nitrodiphenylamine ammonium perchlorate + aluminum). Even higher energy propellants, with the addition of nitramine (HMX), were developed for the Trident and MX missiles.

Hercules Powder is today Alliant Techsystems and builds composite boosters for the Titan IVB, Delta II, Delta III, and the future Delta IV; all stages for Pegasus; and upper stages for the Taurus space launchers. Hercules was a pioneer in the development of fiber-wound light motor cases for Minuteman and Polaris motors.

In the late 1950's and early 1960's, Aerojet tried to develop nitro-urethane as a double-base high energy replacement, but nitrourethane had bad mechanical properties. In the end it has proved that pure double-base propellants are better for the environment than composites, but they are explosive and have relatively low specific impulse (higher with explosive HMX-nitramine added). For safety reasons they are not suited for big space launchers.

Although most solid propellants used today are classed as composites, the double-base (homogeneous) type is still much in demand. However, the gradual increase in the number and amount of additives to the original single-phase double-base propellant has narrowed the distinction between the two classes. Initially the double-base propellant was a homogeneous solid or liquid single-phase chemical system that contained enough oxidizer to sustain combustion in the same molecule with fuel.

MAJOR HERCULES MOTORS. ---------------------------------------------------- Rocket Motor Dia Length Thrust Weight project name inch inch lb lb ---------------------------------------------------- Bumblebee X-201 16 ---- 50,000 +740 Honest John X-202 23 197.44 90,325 3,937 Nike X-216 17.57 135.51 48,700 1,193 Deacon X-220 6.8 110 6,100 155 Improved H.J.X-244 (Improved Honest John) Talos X-251 31.11 138 ----- 4,245 Terrier X-256 18 156.61 ----- 1,839 Altair-1 X-248 18.02 58.21 2,850 513 (Vanguard Thor-Able, Thor-Delta) Altair-2 X-258 19.07 59.25 6,510 576 (Scout-stage 4 Thor-Delta) Antares-1 X-254 30.12 114.68 14,000 2,292 (Scout-stage 3 ) Antares-2 X-259 30.3 113.8 21,700 2,812 (Scout-stage 3 ) Minuteman M-57A1.38 85 ------ ----- (Stage 3) Polaris A2 X-250 54 84.25 ------ ----- (Stage 2) Polaris A3 X-260 54 88.79 ------ 9,501 (Stage 2) Poseidon PC3-1 74.19 187.96 ------ ----- (Stage 1, with Thiokol) Poseidon PC3-2 74 97.265 ------ ----- (Stage 2) Trident I (with Thiokol) Trident II (with Thiokol) MX (third stage) ---------------------------------------------------- =========================================================== Composition of Various Double-Base Propellants (Percent) --------------------------------------------------------- Ingredients Extruded Russian Composite Cast Ballistite Cordite Double- Base --------------------------------------------------------- nitro-cellulose 51.50 56.5 21.0 47.0 nitro-glycerine 43.00 28.0 13.0 37.7 ethyl centralite 1.00 4.5 1.0 1.0 diethyl phthalate 3.25 ---- ---- ---- dimethyl phthalate ---- ---- ---- 14.0 dinitrotoluene ---- 11.0 ---- ---- carbon black 0.20 ---- 9.0 0.3 potassium sulphate 1.25 ---- ---- ---- potassium perchlorate ---- ---- 56.0 ---- --------------------------------------------------------Composite Solid Propellants

Solid propellants of the composite type, containing separate fuel (or reducer, chemically) and oxidizer (in a separate compound) intimately mixed, replaced the simple double-base propellants to a considerable extent, especially for large non-military motors. The organic fuel material is initially in a liquid or semi-liquid form that can set to a solid (binder). Among the earliest substances used were asphalt and various synthetic rubbers. While generally not considered as composite, black powder was in fact the oldest composite propellant. Before 1940 black powder, in common use, was nearly synonymous with the words 'rocket motor' .

While working on the theory of rocket propulsion for his doctoral thesis in 1937, Frank Malina mentioned to Fritz Zwicky of Caltech some difficulties he was having in his study. Zwicky exploded with the opinion that Malina was wasting his time on an impossible subject. For, he said, Malina must realize that a rocket could not operate in space as it required the atmosphere to push against to provide thrust! By 1940 he realized that he was mistaken.

At Guggenheim Aeronautical Laboratory, California Institute of Technology (GALCIT),in 1939, one of the first objectives was to develop a solid propellant rocket unit capable of delivering a constant thrust on the order of 1000 pounds for a period of 10 to 30 seconds. As far as is known, no black powder or smokeless powder rocket had ever been constructed to meet these specifications of thrust and duration. Experts consulted by Malina, John Parsons, and Forman were very dubious about the possibility of doing so.

Preliminary experiments made by Parson and Forman with pressed solid propellant charges restricted to burn cigarette-fashion appeared to support this view. It was generally believed that the combustion chamber pressure of a restricted burning solid rocket unit would continue to rise from the moment of ignition until any combustion chamber of reasonable weight would burst. In other words, it was thought that such combustion was inherently unstable.

The GALCIT group's mentor, Professor Theodore von Karman, in the spring of 1940, had to listen to both the opinions of the experts and to the explosions of Parson's rockets. One evening at home Von Karman wrote down four differential equations describing the operation of an ideal restricted burning motor, and asked Malina to solve them. It was found that, theoretically, a restricted burning unit would maintain a constant chamber pressure as long as the ratio of the area of the throat of the exhaust nozzle to the burning area of the propellant charge remained constant, that is, the process was stable. Experimental verification of the theory was soon obtained.

Although there have been centuries of experiments with black powder rocket, and several investigators used smokeless powder and Ballistite in rockets between about 1918 and 1939, none of these rockets had the thrust and duration required for the aircraft "super-performance" applications. Parsons and Forman in 1938 built and tested a smokeless powder constant-volume combustion motor similar to the one that had been used by Goddard. They concluded after these tests that the mechanical complications of constructing an engine using successive impulses to obtain thrust durations of over 10 seconds was impractical. Upon Parson's recommendation, they concentrated their efforts on the development of a motor provided with a restricted burning powder charge that would burn at one end only at constant pressure to provide a constant thrust.

Parsons started with the traditional sky rocket. This type of pyrotechnic device was propelled by a black powder charge pressed into a cardboard combustion chamber with a conical hole in its center. The gases escaped through a rounded clay orifice. Its efficiency was very, very low, but it was reliable. The conical hole in the charge was believed to be the secret that kept the charge from burning down the sides of the container or to produce chamber pressures that would burst the container. The longest duration of thrust of this motor did not exceed about 1 second.

During 1939 and 1940, various mixtures based on black powder and mixtures of black powder with smokeless powder were tested in 1 in. and 3 in. diameter chambers. The charge for the 3 in. chamber was made up of 6 in. long pellets compressed at around 6,500 psi., and coated with various substances to form a solid or liquid seal between the charge and the walls of the chamber. The charge of the 1 in. chamber was pressed directly into the chamber in small increments at pressures between 7,700 and 12,000 psi. Most of the tests of these charges ended in an explosion.

Mechanical causes for failures, such as burning of the charge on the surface next to the wall because of leakage, transfer of heat down the walls sufficient to ignite the sides of the charge, and cracking of the charge under combustion pressure, were suspected. However, there were those who were convinced that the combustion process of a restricted burning charge in a rocket motor was basically unstable. Only after von Karman and Malina proved the process was stable in their analysis of the characteristics of the ideal solid propellant rocket motor in the spring of 1940 was a concentrated effort was made to study the mechanical causes of failure.

Hundred of tests were then made with different powder mixtures, using black powder as the basic ingredient, with various loading techniques and various motor designs. The dependence of chamber pressure on the ratio of chamber cross section area to nozzle throat area was determined for each specific powder mixture.

By the spring of 1941 the results were sufficiently encouraging to schedule flight tests of an aircraft equipped with solid propellant rockets specially designed for it. The propellant charge used in the Ercoupe motor was a type of amide black powder designated as GALCIT 27 (amide: organic compound containing carbon, hydrogen, oxygen, and nitrogen. Some examples: HCONH2, CH3CONH2, C6H13CONH2). The 2 lb. charge was pressed into the combustion chamber, which had a blotting paper liner, in 22 increments by a plunger with a conical nose shape at a pressure of 18 tons. The diameter of the charge was 1.75 in. and its length varied between 10 and 11 in. The motor was designed to deliver about 28 lb. thrust for about 12 seconds.

Eighteen rocket motors were delivered every other day for the first tests at March Field, California, about an hour's drive from the project. During the first phase of the flight tests one motor failed explosively in a static test and one while Ercoupe was in level flight. Thereafter, 152 motors were used in succession without explosive failure. The motors were prepared by Parsons, Forman, and Fred Miller.

On August 16, 1941, Boushey made the first take-off of the Ercoupe with six JATOs firing. The first American manned flight of an aircraft propelled by rocket thrust alone was made by Boushey on August 23, 1941. The propeller of the Ercoupe was removed and 12 JATO units installed, of which only 11 functioned. The Ercoupe was pulled by a truck to a speed of about 25 m.p.h. before the JATOs were ignited. The airplane left the ground and reached an altitude of about 20 ft. This flight was not originally scheduled but the group could not resist the opportunity to make the improvised demonstration of the future possibility of rocket propulsion.

Frank Malina noted that it was most fortunate that the flight tests were carried out close to the location of the project, which permitted the rocket motors to be fired within a few days from the time they were charged with propellant. Following the flight tests, it was found that after the motors were exposed to simulated storage and temperature conditions over several days they exploded in most cases. It was evident that either the blotting paper liner or the mechanical characteristics of the propellant were unsatisfactory.

But the Navy Department regarded the successful Ercoupe tests with much interest from the point of view of application of rockets for assisted take-off of aircraft from aircraft carriers. Upon the urging of Lt. C.F. Fischer of the Bureau of Aeronautics, who had witnessed the tests, a contract was placed by the Navy with the Project in early 1942 for the development of a 200 lb. thrust, 8 second unit. The unit was designated by the acronym JATO for Jet Assisted Take-Off (sometime RATO), and this designation is still used.

This Navy contract came in the midst of the explosive failure of the JATO unit developed for the Ercoupe tests. All efforts to improve the amide-black powder propellant and loading techniques of the motor developed for Ercoupe tests failed to meet specified storage conditions ranging from Alaska to Africa. Investigations of motors using Ballistite also proved negative, mainly because of its ambient temperature sensitivity (variation of its rate of burning and thrust with ambient temperature).

Thus, the spring of 1942 was one of desperation for those concerned with development of a reliable solid propellant JATO unit. They knew that theoretically it was possible to construct such an engine, but no one came forward with a promising idea until June, when Parsons, no doubt after communing with his poetic spirits, suggested trying a radical new propellant. It would consist of potassium perchlorate (KClO4- in place of potassium nitrate KNO3: saltpeter), as oxidizer, common asphalt as used on roads as a binder and fuel. These could be cast, after being mixed, into a combustion chamber.

A test of the propellant, designated GALCIT 53, was quickly made and the results were so promising that work on other propellant types was dropped for a long time. Parsons was assisted in the development of the asphalt base propellant by Mills and Fred Miller. After due study of the origin of the ideas for the new propellant, Parsons was recognized as its inventor and a patent was granted in his name.

At first, the Ordnance Department objected strongly to the use of potassium perchlorate as an oxidizer because it had proved unsafe in the past. Parsons realized that their objection was no longer valid, since way had been found to produce the material with a minimum purity of 99%. Impurities in the form of dangerous chlorates (KClO3) had been practically eliminated. Sodium and potassium chlorates were used with dinitrotoluen in explosives (know as cheddites in French), also with perchlorates and various hydrocarbons-Vaseline-,castor oil, and nitro. Potassium chlorate was also used as oxidizer in matches with phosphorus sesquisulfide P4S3 or tetraphosphorus trisulfide as the active fuel.

The ruling of the Ordnance Department was thereafter changed, allowing the use of this kind of solid oxidizer. The Navy contract for 100 JATO units delivering 200 lb. thrust for 8 seconds was successfully completed, with GALCIT 53 as the propellant. Production of service-type units for the Navy began shortly thereafter at the Aerojet Engineering Corporation (organized at the end of 1941 and formally incorporated on March 19, 1942 with the GALCIT members Von Karman, Malina, Haley, Parsons, Forman, and Summerfield).

The project carried out extensive studies on asphalt-base propellants in the following years. A detailed report released in May 1944 on the propellant GALCIT 61-C by Mills give the following composition: 76% potassium perchlorate and 24% fuel. The fuel component was 70% Texaco No. 18 asphalt and 30% Union Oil Company Pure Penn SAE No. 10 lubricating oil. The fuel was liquefied at about 275 deg F, the pulverized potassium perchlorate added to it, and the mixture thoroughly stirred. The mixture was then poured into the combustion chamber, which had been previously lined with a material similar to the fuel component, and allowed to cool and become hard. This propellant, when burned at a chamber pressure of 2,000 psi., had a chamber temperature of 3,000-3,500 deg F, a specific impulse of 186, and an exhaust velocity of about 5,900 ft. per sec. Storage temperature limits were from -9 deg F to 120 deg F. GALCIT 61-C was developed in 1943 and used in service JATO units by the Navy until the end of World War II. The propellant is also used on the Private A and F research rockets.

IMPROVEMENTS

Solid propellants utilizing potassium perchlorate as oxidizer produced dense clouds of white smoke (potassium chloride-KCl, like sodium chloride-NaCl, common salt), which the Navy did not like at all. Some months after GALCIT 53 was developed, Parsons informed the Project weekly research conference that he had eliminated the smoke problem by replacing potassium perchlorate with ammonium perchlorate (NH4ClO4). Navy rocket experts were immediately invited to visit the Project for a demonstration:

"When they arrived we posted ourselves some distance from the test pit, the red flag was run up, and Parsons gave the order for his latest creation to be fired. We beheld a big cloud of with smoke and Parsons with a look of surprise on his face. He sheepishly explained that the smoke must have been caused by the humidity, for the air had been very dry on the days they had made tests before".

Ammonium perchlorate does reduce the amount of smoke produced if the air is dry, but it produces undesirable chloride in the jet. In fact Cl and H in NH4ClO4 may combine to form HCl, hydrogen chloride or hydrochloric acid with water. But that is the base of modern composite propellants.

The project also studied the possible use of other fuels instead of asphalt, such as Napalm (sodium palmitate = NaPalm - first tried as a high temperature, high energy propellant), gelled hydrocarbons, gelled wax mixtures, and butyl rubber. A continuation of studies of the last material later led Charles Bartley, under the JPL-ORDCIT Project in 1945, to the discovery of the advantages of the castable elastomeric (polysulfide rubber) material called Thiokol. This discovery became the basis of solid propellant manufacture by the Thiokol Chemical Corporation. The Air Force Material Command terminated work by the Project on solid propellant motors on June 30, 1944. The Ordnance Department, however, continued the work for long range missile applications.

During the course of this research, engineers were provided with methods of motor component design when the following characteristics of the propellant to be used were known:

- Sensitivity of the propellant to ambient temperature during combustion.

- Combustion pressure limit below which the propellant burns in irregular manner.

- Combustion pressure limit above which the propellant burns in an unpredictable manner.

- Storage characteristics of the propellant charge from the point of view of minimum and maximum ambient temperatures allowed and possible decomposition of the propellant with prolonged storage.

- Ignition temperature of the propellant.

- Rate of burning of the propellant as function of the combustion pressure.

- Performance characteristics of the propellant to produce rocket thrust.

Sponsorship of solid-propellant research was taken over by the ORDCIT Project from the Air Force Materiel Command on July 1, 1944. By this time, JPL had made the following fundamental contributions to the design and construction of long-duration solid-propellant engines:

- Theory: Von Karman-Malina theory of constant-thrust long- duration engines (1940)

- Propellant development:

- Parsons' break-away from Ballistite with amide black powder (1940)

- Parsons' introduction of perchlorates as an oxidizer (1942).

- Parsons' introduction of asphalt as fuel-binder with perchlorates; the invention of a castable case- bonded composite propellant charge (1942).

- Parsons' break-away from Ballistite with amide black powder (1940)

- Engine component design

- Parsons' design of a restricted-burning (case- bounded) propellant charge with amine black powder (1940).

- Malina-Mills design of a safety pressure relief valve (1942).

- Mills' review of various types of burning surfaces of a charge and theoretical confirmation that the surface of a cigarette-type burning charge was stable (1943).

- Parsons' design of a restricted-burning (case- bounded) propellant charge with amine black powder (1940).

Since at this time only Aerojet in the USA was producing composite solid-propellant engines, that company's attention was drawn to the asphalt replacement, but it was already interested in a similar material made by the General Tire and Rubber Co. It was only at the urging of the Ordnance Department that the Thiokol Chemical Corp. entered the field of composite solid propellants with the new fuel-binder discovered at JPL.

After obtaining the experience with the composite solid- propellant missiles Private A and F, studies began at JPL in 1946 on larger missiles using, in particular, the polysulfide rubber-perchlorate type propellant. The results of these studies led eventually to the design of the tactical guided missile, Sergeant.

The laboratory followed closely development with other type of solid propellants, especially Ballistite, used in high-thrust short-duration engines suitable for boosters (Aerojet built some double-base boosters using this material).

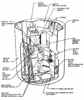

Other special-purpose rocket vehicles supported research in solid propellants and high-acceleration, and high-speed dynamics. A small vehicle unofficially called "Thunderbird" demonstrated the polysulfide composite-propellant, internal-burning star-grain solid motor in 1947. With an acceleration of over 100 G, (a precursor of the Sprint missile) it led to the Wac-scale solid-propellant research vehicle called Sergeant in 1948.

This Sergeant sounding rocket, unrelated to the tactical missile of the same name, proved to be ahead of its time. It was inspired by calculations that indicated a solid-propellant rocket of the internal-burning-star design could deliver several times the payload of a liquid-propelled V-2 type of similar weight. The motor chamber walls were very thin because the propellant, burning from within, would help contain heat and pressure.

An autopilot design effort was begun, and static tests of the motor, weighing 1300 lbs and delivering about 6000 lbs thrust for more than 30 seconds, were conducted.

Difficulties with this solid rocket, manifested in the rupture of the thin-wall case, coincided with a change in the JPL mission and an acceleration and expansion of Corporal development. The Sergeant project was suspended. The electronic autopilot was adopted for the Corporal missile while the solid-propellant engineers took their problems back to the laboratory and test stand for more investigation. Further development was undertaken by the Thiokol Chemical Corporation. The ultimate heritage of this early "Sergeant" powerplant was the reliable solid rocket, used in large scale in the Sergeant and other military missiles, and in clustered miniatures to launch the first Explorer satellites.

The motor evolved from the Sergeant test vehicle of 1948-49 via the Hermes RV-A-10 flight tested in March 1953. A Hermes A-2 Thiokol motor was ground tested in December 1951. The Hermes A-2 program was ended in October 1952.

The Sergeant missile was not the only result of the Thiokol polysulfide motor. Another major development was the Nike-Hercules sustainer motor (or stage two), the Lacrosse motor, and later the Bomarc B motor. Many small missiles, sounding rocket motors, and the Mercury and Gemini retro-rockets used the same propellant.

However, the use of polysulfide by Thiokol probably caused their loss of the key Polaris contract. Aerojet won the contract with the use of a more energetic polyurethane propellant.

After that Thiokol began the use of polybutadiene for big motors and won the contract for the Minuteman first stage motor. That lead as well to the Nike-Zeus, Pershing, Castor motors, Surveyor retro (first of a series of upper stage motors) and finally to the Shuttle SRB's.

Meanwhile, Hercules began the use of double-base propellant as fuel in composite propellants, since double-based motors burned with excess of fuel. The use of a separate oxidizer also permitted the addition of energetic fuels such as aluminum powder.

The excess of fuel in pure double-base caused a long afterburning flame, essentially of burning carbon (see launch-photographs of Nike Ajax and Hercules, Honest John, Terrier, and Talos). The unburned carbon cause also the dark exhaust before the afterburning.

The Hercules' Minuteman third stage was a follow-on of the Vanguard third stage.

Some composite propellants continue to use saltpeter (potassium nitrate) or ammonium nitrate.

Some composite propellant formulations and characteristics:

- Molded composite: potassium nitrate(20-50%), elastomer(10%), ammonium picrate-NH4C6H2NO7-(70-40%). Specific impulse s.l.: 160 to 200 sec. Abundant smoke. Hard to brittle.

- Castable composite: ammonium nitrate(80%), elastomer (18%), catalyst(2%). Specific impulse s.l.: 185 to 198 sec. Little smoke. Soft and resilient to hard and tough.

- Castable composite: ammonium perchlorate(50-85%), elastomer(50-15%). Specific impulse s.l.: 175 to 240 sec. Much smoke at low oxidizer; little at high oxidizer; mist at relative humidity greater than 80%. Soft and resilient to hard and tough.

- Castable composite: potassium perchlorate(50-80%), elastomer(50-20%). Specific impulse s.l.: 165 to 210 sec. Abundant smoke. Soft and resilient to hard and tough.

Ammonium perchlorate is the most widely used today. It is characterized by high heat, is a good gas producer (not a smoke producer), percent of oxygen by weigh: 34 percent, specific gravity: 1.9.

Potassium perchlorate is used for fast burning rates. It is characterized by high heat, is a low gas producer, percent of oxygen by weight: 46 percent, specific gravity: 2.5.

Ammonium nitrate is used for slower burning rates. It is characterized by low heat, is a high gas producer, and is good for gas generator propellants. It requires a greater amount of binder (fuel) to make castable, but too much binder produces excessive smoke. Ammonium nitrate's percent of oxygen by weight: 20 percent, specific gravity: 1.9. It may be the oxidizer for the future. It contains no toxic elements and no solid elements, produces no solids by decomposition, and therefore, together with a high energy non-polluting fuel, could provide a more 'environmentally friendly' solid propellant.

Lithium perchlorate, a proposed oxidizer, is very hygroscopic and may be used in some high-temperature propellants. Percent of oxygen by weight: 60 percent, specific gravity:2.4.

BINDER SYSTEMS

Introduction

The original composite propellants, used in JATO units, contained an asphalt binder. Since asphalt-perchlorate composites had poor performance and formulation characteristics, extensive research and development work was directed toward their improvement. This soon led to the discovery and acceptance of new and better chemical binder-fuels, primarily synthetic rubbers Initially, polysulfide liquid polymers were developed with only physical properties that were an improvement over those of asphalt. Later, with certain chemical-structure modifications, the overall performance of polysulfide soon outshone that of asphalt. Polysulphides, however, had a major drawback in that they released water during combustion; which interfered with efficient burning. The water by-product also limited the type of additives that could be mixed with the propellant, since water was highly reactive with materials such as aluminum. In the search for binder-fuels without the drawbacks of asphalt and polysulfides, polyurethanes (synthetic thermosetting or thermoplastic polymers) were found to have good performance and physical properties. With these aluminum could be incorporated for higher specific impulse. However, polyurethanes were so viscous that the amount of oxidizers and other solid additives that could be incorporated was limited. Eventually polybutadiene- based propellants were developed that had physical properties superior to those of polyurethanes.

Polysulfide

Polysulfide was the first binder elastomer fuel. For rocket applications a low-molecular-weight polymer was made from dichlorodiethyl formal; sodium polysulfide was used as the liquid binder. When the mixture was heated with an appropriate curing agent such as zinc oxide, the links between adjacent polymer chains were joined together to form the rubber network. The resulting binder had a glass-transition temperature near -60 deg F., making it usable to about -40 deg F. This was a distinct advantage over the first composites.

An undesirable quality of the polysulfides was the presence of sulfur atoms in the system. They produced high-molecular-weight exhaust products (sulfur dioxide with a molecular weight of 64) thereby lowering specific impulse. Since a large amount of oxidizer had to be mixed with the binder to obtain the high energy desired, the binder lost much of its rubber-like quality.

There were many organic and inorganic materials that acted as oxidizers and could be used to cure liquid polysulfide polymers. Each had its advantages and disadvantages.

Thiokol developed many varieties of polysulfides with improved qualities.

Polyurethane

Polyurethanes were the second elastomer fuel binder. The group of polymers known as polyurethanes were made by combining polyols with isocianates. The versatility in polymer chemistry was such that a large number of starting materials having varying molecular weights were available.

Compared with the polysulfides, the average molecular weight of the polyurethanes' exhaust gases was lower. This was because the polyurethanes contained only carbon, hydrogen, oxygen, and nitrogen atoms (not sulfur). An additional benefit was claimed in the processing: the backbone polymer contained substantial amounts of oxygen. It was not necessary therefore to use as great a percentage of oxidizer in the formulation of the propellant to achieve comparable energies. The increased proportion of binder to oxidizer provides added elongation and other good mechanical properties to the propellant, permitting the addition of other energetic fuels (for example aluminum).

From the logistics standpoint, the starting ingredients for manufacturing polyurethane were available from a large number of chemical suppliers, whereas the liquid polysulfide rubbers were manufactured almost exclusively by a single company. This had its effect on cost, quality, and delivery time.

One of the advantages of polyurethane was that a high concentration of nitrate ester could be incorporated in the binder to give increased energy. A commonly used polyurethane binder material was ESTANE, a product of B.F. Goodrich Chemical Company.

Polybutadiene.

Polybutadiene Acrylic Acid.

Almost concurrently with the evolution of the polyurethane propellants, a new type of binder based on long-chained polybutadiene backbone gained the attention of rocket manufacturers. The selection of polybutadiene binder for propellants to be used over wide temperature ranges was a natural one, since most butabiene copolymers (butadiene-styrene, butadiene-acrylonitrile, butadiene- methylvinyl pyridine) had glass-transition temperatures near or below -100 deg F. This was advantageous, since the mechanical behavior of a propellant during periods of strain was related to its properties at different temperatures. For example, the ability of a propellant to withstand high strain rates such as those encountered on ignition of a large-diameter rocket motor was directly related to low-temperature properties such as elongation and brittle point. Therefore, the polybutadiene propellants were attractive, both for large motors and for those requiring wide temperature ranges of operation.

Probably the most widely used polybutadiene polymer (1967) had been PBAA, a copolymer of polybutadiene and acrylic acid. One of the added benefits of PBAA over polyurethane was that the binder system was less complex, consisting essentially of the liquid polymer and a single curative chemical such as an epoxide resin. In certain formulations where a large amount of oxidizer and an auxiliary metal-powder fuel such as aluminum was needed to provide high energy, it was necessary to add to the binder a liquid hydrocarbon or other low-viscosity fluid that acted as a plasticizer to aid in processing.

By contrast, the polyurethane system normally consisted of a main chain polymer such as a polyether diol, a shorter chain cross-linking agent (perhaps a trifunctional polyol), a curing agent (isocyanate) and a curing catalyst; polyurethanes also employ plasticizers where necessary, usually in the form of aliphatic esters such as dioctyladipate or dioctylsebacate.

Carboxy-Terminated Polybutadiene.

Throughout the 1950's propellant manufacturers depended mainly upon rubber chemicals that were readily available to provide the material used in the binders. Among these were PBAA, and the polyethers and polyesters used in polyurethane propellants.

However, at the beginning of the 1960's the designers of weapon systems appeared to be moving ahead of the propellant manufacturers from the standpoint of operational requirements. Thus it was necessary for the propellant research chemist to visualize the "perfect molecular structure" that would best fulfill the need, and then either make the material or work with a chemical supplier to make it.

The first of these custom-made polymers, pioneered by Phillips Petroleum Co. and first evaluated in propellant applications by Rocketdyne, was carboxy-terminated polybutadiene (CTPB). There was an advantage in placing the carboxyl groups at the end of the polymer chain rather than randomly spacing them along the chain (as PBAA polymers). This way the polymer chemist was provided with a uniform structure so he could control his binder network to give the desired mechanical properties. The reproducibility of a controlled system was naturally greater than that of a random structure.

However, the demand by the customer (primarily the US Government) for greater reliability and overall improved performance suggested that still better binders would be forthcoming. To improve reliability of the CTPB system, for example, a greater insight was needed into the affects of molecular weight and molecular-weight distribution. The influence of molecular structure (isomeric configuration) and minor impurities on mechanical properties was to be determined as part of the continuing research and development.

The interplay of mechanical forces between the binder, the aluminium particles, and the ammonium perchlorate crystals would have to be researched until greater knowledge was attained. Information on such fundamentals as energy of wetting, surface free-energy of the solids, the effect of these properties on cracking or other mechanical failure, kinetics of cross-linking reaction, and the effect of temperature and moisture on cure reversion was needed.

There was no doubt that knowledge in these areas would bring about improved hydrocarbon binders.

PBAN - Polybutadiene Acrylic Acid Acrylonitril Terpolymer (PBAN).

This was the formulation widely used on the 1960-70's big boosters (Titan III & Shuttle).

HTPB - Hydroxyl-Terminated Polybutadiene.

HTPB was the most recent state-of-the-art composite propellant binder, manufactured by ATOChem, Inc. (Boosters: Delta II, Delta III, future Delta IV, Titan IVB and Ariane).

NEW BINDERS TO MEET CLEAN AIR REQUIREMENTS.

Environmental concerns regarding the combustion products of large solid rocket motors used in space launch applications led to a number of 'environmentally friendly' binders being proposed.

GAP: Glycigyl azide polymer, a developmental energetic binder produced by 3M Co. and developed at Valcartier, near Québec, Canada.

Poly-NMMO: Poly-nitratomethyl, methyl oxetane, a developmental energetic binder with a high oxygen content, by Aerojet Solid Propulsion Co.

BTTN: Butanetrioltrinitrate, a highly oxygenated energetic plasticiser.

DMBT: Dimethylbitetrazole, a developmental high nitrogen solid fuel with a high positive heat of formation, used in propellants with oxidisers having high oxygen balances to increase performance, developed at NAWCWPNS.

Developments Outside of the USA

Other countries begin to study modern composite propellants around mid-1950. Polysulfide remained a nearly an exclusive product of Thiokol. In 1957 design bureau TsKB-7 in the USSR began the study of solid propellants for the D-6 SLBM system, but the technology was not mature. Beginning in 1961 TsKB-7 build the second and the third stages for the Korolev RT-2 ICBM (US code name SS-13 Savage), but the composite propellant technology in USSR remained many years behind that of the west. The RT-2 first flight was in 1966. Beginning in 1961, development began of the RT-15/8K96 mobile IRBM using two stages from the RT-2. The RT-15 would have a range of 4,500 km with a 1.4 tonne payload. However the project was abandoned in 1970 after 19 test launches.

PROPELLANT ADDITIVES

To help provide the high-energy propellants that were required for the more efficient space vehicles and missiles, many propellants used special fuel additives such as powdered metals. Powdered aluminium was used extensively in propellant formulation for the extra energy it contributed and for the help it gave in promoting stable burning. Although powdered beryllium had a higher theoretical energy value than aluminium, it was seldom used because of its extreme toxicity, relative scarcity, and higher cost. In addition, beryllium had a poor combustion efficiency with most of the hydrocarbon binder-fuels available. However, this could be improved by using it with unique and advanced binders like fluorocarbons.

THE SEARCH FOR HIGH ENERGY PROPELLANTS

After WW II, with the Cold War and the prospect of space travel, the search for exotic, energetic fuel was the rule. Boron was the star during the 1950s, but things changed during the 1960s and 1970s. Rocket fuel selection began with an evaluation of the elements from which candidate fuels were, or may be composed. The calculated variation in adiabatic combustion temperature for an oxygen reaction with some of the elements had been reported by Grosse and is reproduced in the table here.

These temperatures varied considerably and showed that some heavy elements were capable of producing even greater temperatures than light elements such as hydrogen and carbon. However, the heavy elements could quickly be eliminated from consideration (however note that the combustion temperatures would be different with fluorine or other oxidisers). A few, such as zirconium and titanium, were merely competitive on a volumetric heating value basis (BTU/cu ft) and considerably inferior on a gravimetric basis (BTU/lb). Light elements, such as hydrogen, lithium, beryllium, boron, carbon, magnesium and aluminium, appeared interesting.

Only hydrogen, beryllium and boron had higher heating value than the usual hydrocarbons (HC=~18-19). Beryllium was scarce and extremely toxic, and does not at this time merit serious consideration. High energy fuels, therefore, quickly become restricted to hydrogen and boron and a few classes of compounds containing hydrogen or boron. Special purpose fuels could also involve compounds containing lithium, magnesium, aluminium or carbon. (if one notes that a lighter element goes faster (exhaust velocity) for the same combustion temperature, it can be seen that the carbon and sulphur of black powder, and the sodium in Napalm, were very poor fuels).

EXTOTIC, HIGH ENERGY SOLID PROPELLANTS - THE VIEW IN THE 1960s.

Space and military applications stimulated chemical research so that many exotic and highly reactive ingredients for solid-propellant rockets were produced.

The oxidisers in use consisted of weakly held oxygen atoms in chlorine and nitrogen compounds. It was thought that future oxidisers would have less chlorine and nitrogen atoms, and most of the oxygen would be replaced by fluorine. Some oxygen would remain for the purpose of burning the carbon in the binder to carbon monoxide. Fluorine would be linked to oxygen and nitrogen atoms, with which it forms weak bounds. Nitronium perchlorate and its fluorine derivative (nitronium perfluorate?) were outstanding oxidisers at that time.

Fuels would be light-metal hydrides then known, but efforts would be made to replace these by less reactive hydrides of mixed nature. The fuel would be a light-metal hydride with a low heat of formation-one which yields fluorides and oxides with the highest heat of formation. Since rockets using exotic propellants would have a limited volume, the density of the propellant was of critical importance. The best fuels would be light-metal hydrides of low density, a factor which must be considered in the selection of the oxidiser and binder.

A major problem was to solve that of preventing the oxidiser and fuel from reacting with each other and with the organic polymeric binder material. Binders would have to be developed which were inert to the fuel and oxidiser. In addition, binders would have to prevent chemical interaction of fuel and oxidiser to avoid possible propellant explosions. The most likely binders would contain long chains of carbon atoms bearing fluorine atoms- (CF2)n -fluorocarbons). The fluorine would serve to consume the fuel and produce inert polymers. These binders would contain little hydrogen since the metal hydrides contained loosely held hydrogen. The performance of these future solid propellants would probably range from 285 to more than 300 seconds. The ultimate solid propellant (specific impulse of up to 350 seconds) would be composed of a binder containing sufficient oxygen to convert its carbon monoxide. A maximum of fluorine-oxygen-carbon groups was also desirable.

Binders more dense than the (CF2)n structure previously mentioned would be difficult to achieve since its density was 50 to 60 percent greater than conventional hydrocarbon binders. In view of compatibility problem with solid propellants, hybrid-propellant systems would have to be developed. Some liquid fuels and oxidisers were superior to their solid counterparts, so the hybrid system should be able to achieve performances which were superior to those of solid propellants.

EXOTIC INGREDIENTS - THE VIEW IN THE 1960s

The development of propellants with higher energy (250-300 Isp) and increased thermal stability (300°F- 500°F) necessitated the incorporation of some exotic chemicals into solid propellants and related devices. Many of these compounds had unusual hazards associated with their uses that were not immediately evident. Others had been used in various phases of research and development and had recognised toxic or explosive properties. The following section lists, with brief comments, some of the more important of these chemicals that were then used in the development of new propellants.

OXIDIZERS.

- Nitronium perchlorate or NP (NO2ClO4)-Nitrosyle

- Toxicity- Decomposes above 80°C or in contact with water and many organic compounds. The decomposition of NP releases oxides of nitrogen (NO,NO2) and chlorine (Cl2). Maximum allowable concentration are 5 ppm.

- Sensitivity- Mixtures of NP with nearly all organic compounds are dangerous and explosives and are apt to explode spontaneously. Mixtures with other oxidisable materials behave similarly.

- Uses- Proposed for use in high-energy propellants.

- Lithium perchlorate or LP (LiClO4)

- Toxicity- Not toxic unless large amounts taken orally.

- Sensitivity- Same as potassium perchlorate. Mixtures with reducing agents are explosives (class B).

- Uses- High-temperature propellants.

- Hydrazinium diperchlorate or HP (N2H6(ClO4)2)

- Toxicity- Decomposes to give chlorine gas (Cl2).

- Sensitivity- Very hazardous material to handle. Extremely sensitive to impact and friction. Low auto-ignition temperature.

- Uses- High-energy propellants.

- Lithium aluminium hydride or LAH (LiAlH4)

- Toxicity- Dust was very irritating since it contains lithium hydroxide.

- Explosive Hazards- Very dangerous to handle since it may ignite and burn violently. Dust may explode. Ignites spontaneously with water, alcohols, ammonium hydroxide, etc.

- Uses- High-energy fuel.

- Magnesium hydride (MgH2) and Lithium borohydride (LiBH4)

- Toxicity- MgH2 was relatively non-toxic. LiBH4 was toxic and may release diborane (B2H6) on treatment with acids. B2H6 (also proposed in liquid fuel in the 50s, on B-70 for example) was extremely toxic, with a maximum allowable concentration less than 1 ppm.

- Hazards- MgH2 and LiBH4 are much less hazardous than LiAlH4. They are similar to Mg powder, and release hydrogen.

- Uses- High-energy fuel.

Powdered metals such as Zirconium (Zr) and Beryllium (Be)

- Toxicity- Dust should not be inhaled. Beryllium dusts are very toxic.

- Hazards- Finely powdered Zr was ignited by static electricity. Some powders are pyrophoric. Mixtures with oxidising agents are hazardous and easily exploded by static electricity.

- Uses- Zr was used in igniters and various pyrotechnic devices while beryllium was an additive in high-energy propellants.

- Nitrourethanes or NU

- Toxicity- All nitro compounds are toxic, some extremely so. Many are absorbed through the skin. Some may cause dermatitis. The alisocyanates from which nitrourethanes are prepared are extremely hazardous.

- Sensitivity- Nitrourethanes are generally class-C explosives, but a few may be more sensitive.

- Uses- High energy propellants.

- Nitramines (HMX, RDX)

- Toxicity- Most similar to nitro compounds but more variable, depending on structure. Some may cause severe dermatitis.

- Sensitivity- Some are class-B explosives. Nitrourethanes mixed with this group are generally class C.

- Uses- Experimental only. (1967)

- Tetrazoles

- Toxicity- Toxic properties not well established but some are apparently non-toxic.

- Sensitivity- Some propellants and pyrotechnic devices using tetrazoles accidentally exploded, causing several injuries. These devices are regarded as extremely hazardous.

- Uses- Various pyrotechnic devices.(derivatives in high-energy propellants)

- Fluorocarbons or FC

- Toxicity- While many FC compounds are completely non-toxic, some are extremely toxic. Pyrolysis of many fluorocarbons may yield gaseous, odourless compounds of extreme toxicity. Kel-F, teflon, and other FC polymers release fluorolefins on heating which among the most toxic of gases. Combustion of FC propellants release toxic gases (hydrogen fluoride).

- Sensitivity- FC derivatives are not explosive unless mixed with certain powdered metals, metal hydrides, and metallorganic derivatives. These mixtures are not easily exploded by shock, but are exploded by heating.

- Uses- Experimental only.

- Plasticizers

- Toxicity- Many are relatively non-toxic but some of the nitrated or fluorinated materials must be regarded as toxic. Nitrocompounds are absorbed through the skin and cause dermatitis. Dinitriles are toxic; they are absorbed through the skin.

- Sensitivity- All insensitive, except some nitro or nitramino plasticiser.

- Uses- Improved propellants.

Propellant Tables

Calculated Variation In Adiabatic Combustion Temperature

For An Oxygen Reaction With Certain Elements

As Reported By GrosseAtomic Number Atomic Weight Element Temperature of Combustion deg R Heating Number Value BTU/LB 1 ~1 hydrogen ~5,400 ~52 2 ~4 helium inert 3 ~7 lithium ~4,700 ~18 4 ~9 beryllium ~7,900 ~28 5 ~10 boron ~5,400 ~26 6 ~12 carbon ~3,700 ~14 7 ~14 nitrogen ~( 2,200) quasi-inert with O 8 ~16 oxygen .......... oxidizer 9 ~19 fluorine .......... oxidizer 10 ~20 neon .......... inert 11 ~23 sodium ~3,800 ~4 12 ~24 magnesium ~6,100 ~11 13 ~27 aluminum ~7,000 ~13 14 ~28 silicium ~4,600 ~12 15 ~31 phosphorus ~(2,400) ~11 16 ~32 sulphur ~(1,800) ~4 17 ~35 chlorine ~(400) oxidizer 18 ~40 argon .......... inert 19 ~39 potassium ~3,100 ~2 20 ~40 calcium ~6,900 ~7 21 ~45 scandium ~7,100 ~8 22 ~48 titanium ~6,000 ~9 23 ~51 vanadium ~6,000 ~7 24 ~52 chromium ~6,000 ~6 25 ~55 manganese ~6,200 ~5 26 ~56 iron ~5,500 ~4 27 ~59 cobalt ~(4,300) ~3 28 ~59 nickel ~(3,000) ~2 29 ~64 copper ~2,200 ~1 30 ~65 zinc ~4,000 ~3 31 ~70 gallium ~4,900 ~3 32 ~73 germanium ~5,600 ~3 33 ~75 arsenic ~(3,000) ~3 34 ~79 selenium ~(1,700) ~3 35 ~80 bromine ~(400) oxidizer~236 ~84 krypton ~....... inert 37 ~85 rubidium ~2,900 ~1 38 ~88 strontium ~6,400 ~2 39 ~89 yttrium ~7,400 ~3 40 ~91 zirconium ~8,700 ~4 41 ~93 niobium ~7,300 ~3 42 ~96 molybdenum ~5,500 ~2 43 ~99 technetium ~........ ~1 44 ~101 rubidium ~........ ~1 45 ~103 rhodium ~........ ~1 46 ~106 palladium ~1,300. .~1 47 ~108 silver ~1,200 ~1 48 ~112 cadmium ~3,100 ~1 49 ~115 indium ~4,100 ~1 50 ~119 tin ~4,900 ~2,5 51 ~122 antimony ~3,100 ~2 52 ~128 tellurium .......... ~2 53 ~127 iodine .......... ~1 54 ~131 xenon .......... inert 55 ~133 cesium ~2,700 ~1 56 ~137 barium ~5,400 57 to 71 : rare earths 72 ~178 hafnium ~8,700 73 ~181 tantalum ~(7,600) 74 ~184 tungsten ~5,800 75 ~186 rhenium ~(4,000) 76 ~190 osmium ~(1,800) 77 ~193 iridium ~(1,400) 78 ~195 platinum ~800 79 ~197 gold ~600 80 ~201 mercury ~1,000 81 ~204 thallium ~(2,000) 82 ~207 lead ~3,200 83 ~209 bismuth ~3,600 84 ~210 polonium ~(2,100) 85 ~210 astatine ~(1,000) 86 ~222 radon ......... inert 87 ~223 francium ~2,400 88 ~226 radium ~4,500 89 ~227 actinium ~7,000 90 ~232 thorium ~9,000 Some double-base propellant compositions:

J.P. powder:

Nitrocellulose(13.25%N2): 52.2%

Nitroglycerin: 43.0%

Diethyl phthalate: 3.0%

Diphenylamine: 0.6%

Potassium Nitrate(saltpeter): 1.1%

Nigrosine: 0.1%J.P.N. powder:

Nitrocellulose(13.25%N2): 51.50%

Nitroglycerin: 43.00%

Diethyl phthalate: 3.00%

Ethyl centralite: 1.00%

Potassium sulfate: 1.25%

Carbon black: 0.20%

Candelilla wax: 0.05%Slow burning powder:

Nitrocellulose(12.2%N2): 56.5%

Nitroglycerin: 28.5%

Dinitrotoluene: 11.0%

Ethyl centralite: 4.4%

Candelilla wax: 0.1%--------------------------------------------------- Relative value of Specific Impulse: Black powder:-----------------------~125 sec. Double-base:------------------------~200 sec. Cellulose acetate+ammonium nitrate: ~175 sec. Asphalt+ammonium perchlorate:-------~180 sec. Polysulfide+ ":---------------------~200 sec. Polyurethane+":---------------------~225-230 sec. Polybutadiene+ ":-------------------~230-235 sec. Polyurethane+ Aluminum + " :--------~240 sec. Polybutadiene+ Aluminum + ":--------~245 sec. PBAA + Aluminum + ":----------------~250 sec. Composite/double-base:--------------~275 sec. ---------------------------------------------------

List Of Ingredients Used In Double-Base Propellants

Plasticizer (Fuel And Oxidizer) --NG: nitroglycerin --TMETN: trimethylolethane trinitrate --TEGDN: triethylene glycol dinitrate --DEGDN: diethylene glycol dinitrate

Plasticizer (Fuel) --DEP: diethylphtalate --TA: triacetine --PU: polyurethane

Binder (Fuel And Oxidizer) --NC: nitrocellulose

Stabilizer --EC: ethyl centralite --2NDPA: 2-nitrodiphenilamine

Burning Rate Catalyst --PbSa: lead salicylate --PbSt: lead stearate --Pb2EH: lead 2-ethylhexoate --CuSa: copper salicylate --CuSt: copper stearate --LiF: lithium fluoride

High Energy Additive --RDX: cyclotrimethylene trinitramine --HMX: cyclotetramethylene tetranitramine --NGD: nitroguanidine

Coolant --OXM: oxamide

Opacifier --C: carbon black

Flame Supressant --KNO3: potassium nitrate (saltpeter) --K2SO4: potassium sulfate

Metal Fuel --Al: aluminum

Combustion Instability Suppressant --Al: aluminum --Zr: zirconium --ZrC: zirconium carbide

List Of Ingredients Used For Composite Propellants

Oxidizer

--AP: ammonium perchlorate

--AN: ammonium nitrate

--NP: nitronium perchlorate

--KP: potassium perchlorate

--RDX: cyclotrimethylene trinitramine

--HMX: cyclotetramethylene tetranitramine

Binder

--PS: polysulfide

--PVC: polyvinyl chloride

--PU: polyurethane

--CTPB: carboxyl terminated polybutadiene

--HTPB: hydroxyl terminated polybutadiene

Curing And/Or Crosslinking Agents

--PQD: paraquinone dioxime

--TDI: toluene-2,4-diisocyanate

--MAPO: tris(1-(2-methyl) aziridinyl) phosphine oxide

--ERLA-O51O: N,N,O-tri (1,2-epoxy propyl)-4-aminophenol

--IPDI: isophorone diiosocyanate

Bonding Agent

--MAPO: tris( 1-(2-methyl) aziridinyl) phosphine oxide

--TEA: triethanolamine

--MT-4: adduct of 2.0 moles MAPO, 0.7 mole azipic acid,

………and 0.3 mole tararic acid

Plasticizer

--DOA: dioctyl adipate

--IDP: isodecyl pelargonete

--DOP: dioctyl phthalate

Burning Rate Catalyst

--Fe2O3: ferric oxide

--FeO(OH): hydrated ferric oxide

--nBF: n-butyl ferrocene

--DnBF: di-n-butyl ferrocene

--LiF: lithium fluoride

Metal Fuel

--Al: aluminum

--Mg: magnesium

--Be: beryllium