Home - Search - Browse - Alphabetic Index: 0- 1- 2- 3- 4- 5- 6- 7- 8- 9

A- B- C- D- E- F- G- H- I- J- K- L- M- N- O- P- Q- R- S- T- U- V- W- X- Y- Z

Lunex

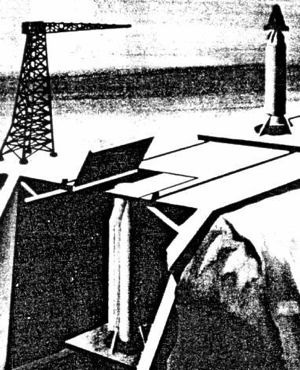

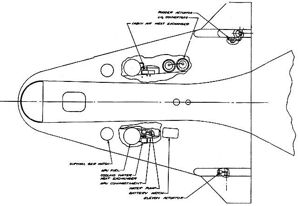

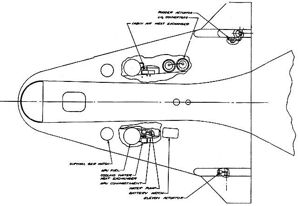

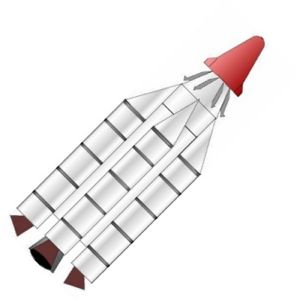

Lunex Lunar Lander USAF Lunex lunar lander. The Lunex lifting body re-entry vehicle, for three crew, is mounted atop the Lunar Launching Stage, which in turn is nested in the Lunar Landing Stage. |

Status: Study 1958.

In May 1961, just as Kennedy had decided that NASA should put an American on the moon, the US Air Force released a secret report, summarizing the result of years of planning to place a military base on the moon by 1967. Lunex was not a race against the Russians, but rather a plan to achieve the 'strategic high ground'. It is interesting to note the following:

- If Project Lunex had been pursued instead of Apollo, the United States would have ended the sixties with a launch vehicle very similar to the Shuttle - solid rocket boosters, a Lox-LH2 core, a lifting re-entry vehicle. This clearly could have provided a better basis for follow-on programs than Apollo did. The USAF launch vehicle studies of the late 1960's again came up with a very similar configuration, and NASA finally came to the same conclusion for the Shuttle design as well. One advantage of the Lunex booster is that it also provided a heavy-lift launch vehicle in the pure cargo version.

- The report reveals the reason for USAF support of development of the advanced and large rocket engines begun in the late 1950's: the LR-115 (RL-10), J-2, F-1, M-1, and large solid rocket motors. The RL-10, designed for the USAF from the beginning as a throttleable motor for the Lunex lunar lander, finally put this capability to use twenty years later in the DC-X VTOL vehicle.

- The schedule was extremely over-optimistic. First lunar landing was by the end of 1966, while the booster and vehicle were considerably more advanced than the Apollo approach. Examples include:

- Lox-LH2 in the lunar landing stages, including throttleability and months-long lunar hibernation times between engine restarts

- Mach 35 lifting body re-entry vehicle

- Computer data storage capabilities and technologies not even achieved today

- Electrostatic gyro platforms (not perfected until the late 1970's in the B-52's SPN-GNS platform)

- Many of the techniques for Project Lunex reappear in Korolev's early L3 lunar expedition plans. These include the selection of base sites by automated probes; the planting of homing transponders on the lunar surface for precision landing of manned landers and cargo craft (by Surveyor spacecraft in Lunex, by Luna Ye-8 landers and Lunokhods in the Russian plans); and methods of direct lunar landing.

- The Intelligence Section contains a mixture of erroneous beliefs as to the characteristics of the booster stages of the R-7 launch vehicle, mixed with some accurate intelligence on the upper stages (calculable from tracking and telemetry intercepts for Turkey). It would seem that as of this date no accurate intelligence or photograph of the R-7 vehicle on the pad had been made. The information as to Soviet intentions (no plans to go to the moon) was more accurate. It would seem that both the USAF and Kennedy picked the moon goal as one in which the Russians were not really interested.

LUNAR EXPEDITION PLAN - LUNEX

<

LUNEX

HEADQUARTERS

SPACE SYSTEMS DIVISION

AIR FORCE SYSTEMS COMMAND

DOWNGRADED AT 12 YEAR

This document provides a plan for a manned Lunar Expedition. It was prepared to furnish more detailed information in support of the National Space Program proposed by a USAF committee chaired by Major General J R Holzapple. That report pointed out the dire need for a goal for our national apace program. The Lunar Expedition was chosen as the goal since it not only provides a sufficient challenge to the nation, but also provides technical fall-outs for greatly improved apace capabilities.

Previous editions of this plan have provided guidance and incentive to Air Force technical groups. Consequently, their efforts have established a broad technical base within the Air Force from which rapid advances can be made. This capability has been taken into account in laying out the accelerated schedules in this plan.

O J RITLAND

This document contains information affecting the national defense of the United States within the meaning of the Espionage Laws, Title 18, U S.C. Section 793 and 794, the transmission or revelation of which in any manner to an unauthorized person is prohibited by law

I. SUMMARY

II. PROGRAM DESCRIPTION

III. MASTER SCHEDULES

IV. DEVELOPMENT- TEST - PRODUCTION

V. BUDGET AND FINANCIAL

VI. PROGRAM MANAGEMENT

VII. MATERIEL SUPPORT

VIII. CIVIL ENGINEERING

IX. PERSONNEL AND TRAINING

X. INTELLIGENCE

Appendix #1 Glossary of Terms

FOR

LUNAR EXPEDITION

Approved by

Norair M. Lulejian

WDLAR-S-458

SECRET

LUNAR EXPEDITION

PLAN

Lunex Lunar Lander

USAF Lunex lunar lander. The Lunex lifting body re-entry vehicle, for three crew, is mounted atop the Lunar Launching Stage, which in turn is nested in the Lunar Landing Stage.

MAY 1961

INTERVALS. NOT AUTOMATICALLY

DECLASSIFIED. DOD DIR 5200.10

WDLAR-S-458

SECRET

AIR FORCE SYSTEMS COMMAND

Major General, USAF

Commander

CONTENTS

Colonel, USAF

Director, Advanced

Systems Plans and Analysis

SECTION I - SUMMARY

1.1 PURPOSE

The Lunar Expedition has as its objective manned exploration of the moon with the first manned landing and return in late 1967. This one achievement if accomplished before the USSR, will serve to demonstrate conclusively that this nation possesses the capability to win future competition in technology. No space achievement short of this goal will have equal technological significance, historical impact, or excite the entire world.

1.2 BACKGROUND

Extensive studies by Air Force-Industry teams during 1958, 1959, and 1960 examined all facets of the problem and techniques of sending men to the moon and resulted in a feasible concept which is attainable at an early date and is economical and reliable. Laboratories within the Air Force participated in this effort, thus establishing a broad technological base which can react quickly to an expanded high priority program.

1.3 DESCRIPTION

The lunar mission would be initiated by the launching of the lunar payload by a large, three-stage liquid or solid propellant booster to escape velocity on a lunar intercept trajectory. The payload, consisting of a Lunar Landing Stage, Lunar Launching Stage and a manned vehicle, would use a lunar horizon scanner and a Doppler altimeter for orientation prior to a soft landing using the Lunar Landing Stage. Terminal guidance using pre-positioned beacons would be required for landing at a pre-selected site. The Lunar Launch Stage would provide the necessary boost for the return to earth of the manned Lunex Re-entry Vehicle. Using mid-course guidance and aerodynamic braking, the vehicle would effect re-entry and a normal unpowered aircraft landing at a ZI base.

In addition to the manned vehicle a cargo payload is included in this plan. The cargo payload would utilise the same three-stage earth launch booster and the same lunar landing techniques. However it would not be returned to earth and would be used only to transport supplies and cargo to the expedition on the moon.

The primary concept recommended in this plan is the "direct shot" method since studies have indicated it could be available at an earlier date and it would be more reliable. Another concept is also suggested which consists of the rendezvous and assembly of components in an earth orbit before ejection into a lunar trajectory. The techniques and development required for this latter concept are documented under a separate SSP titled, SAINT. Therefore, no details of this concept are presented in this plan. All schedules relating the two plans have been co-ordinated to insure compatibility and to take advantage of mutual advances. Since neither rendezvous techniques nor large boosters have been demonstrated, both approaches must be pursued until it becomes obvious that one of them has clear advantages over the other.

The following developments are required in order to accomplish the lunar expedition:

a. A three-man Lunex Re-entry Vehicle. This vehicle must be capable of re-entry into the earth's atmosphere at velocities of 37, 000 ft/sec. It must also be capable of making a conventional aircraft landing. Control and improved guidance for entering the earth's atmosphere at the proper place and angle is needed as well as improved materials to withstand the high surface temperatures. Adequate life support equipment is also required. The development of this vehicle is the key to the accomplishment of the Lunex program and is one of the pacing development items. A detailed schedule for its development is included.

b A Lunar Landing Stage for decelerating and landing the entire payload. This stage must have the capability to decelerate 134,000 pounds from a velocity of almost 9,000 ft/sec to 20 ft/sec at touchdown. A Doppler altimeter is required to provide information for ignition and control of the engine. Horizon scanners must be used to orient the payload to the local vertical.

c. A Lunar Launch Stage capable of launching the manned Lunex Re-entry Vehicle from the lunar surface. Lunar ascent guidance is required to place the vehicle on the proper trajectory.

d. A three-stage earth launch booster, referenced as a space launching system. The first stage will use either LOX/LH2 with six million pounds of thrust or a solid fuel with an equivalent launch capability. The second and third stages will use LOX/LH2. The development of this space launching system is considered the pacing development item for the Lunex program. Because of the magnitude of the booster program and the applicability of the booster to other programs, the plan for its development is being presented separately.

In addition to the above listed hardware developments, additional information is required about the lunar surface such as its physical and roughness characteristics. High resolution photographs of the entire lunar surface may provide this information. Present NASA plans if expedited could provide the information for this Lunex program. NASA's Surveyor (soft lunar landing) program could also incorporate radio-light beacons which would be used later in conjunction with a terminal landing system. A core sample of lunar material is required as soon as possible so that design of lunar landing devices and lunar facilities can be accomplished.

1.4 MAJOR PROBLEM AREAS

The development of techniques for re-entering the earth's atmosphere at 37,000 ft/sec is one of the major problems. Guidance equipment must be very accurate to insure that the re-entry angle is within +- 2°. Too steep an entry angle will cause overheating and intolerable G loads, while too shallow an entry angle may permit the Lunex Re-entry Vehicle to skip out of the atmosphere into a highly eccentric earth orbit. If this happens, the vehicle may spend several days in the trapped radiation belts and may exceed the time limits of the ecological system.

The Lunar Landing Stage will be a difficult development because of a requirement for orientation with the local vertical when approaching the moon. It must also be guided to the selected landing site. Many tests will be required to develop the necessary equipment.

The Lunar Launching Stage will be another difficult development. The pre-launch countdown must be performed automatically and, if the launching booster is not vertical upon launch, corrections must be made in order to attain the required moon-earth trajectory.

Although the foregoing developments are difficult, no technological break-through will be required. All designs can be based on extrapolation of present technology.

1.5 MILESTONES

Major milestones in the program are:

a. Recovery of a manned re-entry vehicle from 50,000 miles in 1965.

b. Manned Circumlunar flight in 1966.

c. Manned lunar landing and return in 1967.

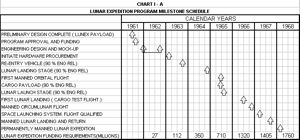

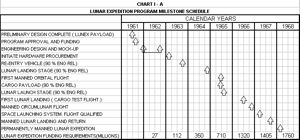

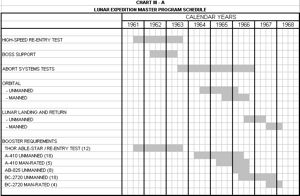

These and other significant events are shown on Chart I-A.

1.6 CAPABILITIES DEVELOPED

The development of large boosters, rendezvous techniques and manoeuvrable space vehicles, all required for the Lunar Expedition, will also provide a capability for many new and advanced space achievements. For example, the Space Launching System which will boost 134,000 pounds to escape velocity will boost approximately 350,000 pounds into a 300 nm orbit, or will launch a manned vehicle on a pass around either Mars or Venus.

1.7 MANAGEMENT ACTIONS REQUIRED

The major Management Milestones for FY62 and FY63 are shown on Chart I-B. Immediate attention by Management to obtain Program Approval and Funding by July 1961 is necessary if the United States is to put a "man on the moon" by August 1967.

Throughout the Lunex program time allocated for management and Air Force technical evaluations has been kept to a minimum. This is essential to meet the schedules, and delays in providing funding as indicated, or in receiving notification of required decisions, will have the direct effect of delaying the program end objective.

SECTION II - PROGRAM DESCRIPTION

2.0 BACKGROUND

Shortly after the first Sputnik was launched in October 1957, Headquarters, ARDC initiated a series of studies to examine the military potential of space operations. These studies were accomplished by Industry-Air Force teams each working independently. Two of these studies which were the forerunners of this Lunex plan were "Lunar Observatory" and "Strategic Lunar System." The objective of the first study was to examine an economical, sound and logical approach for establishing a manned intelligence observatory on the moon, and the second study examined the military potential of lunar operations. These studies showed that it is technically and economically feasible to build a manned lunar facility.

A third study titled, "Permanent Satellite Base and Logistic Study" is presently under way and will be completed in August 1961. This study will provide a conceptual design of a three-man re-entry vehicle which will carry men to and from the moon. The three-man vehicle is the key item in the lunar transportation system as its weight will dictate the booster sizes. For this reason it is given special attention in this plan.

2.1 Lunex PROGRAM OBJECTIVE

The objective of the Lunar Expedition program is the manned exploration of the moon with the first manned lunar landing to occur as soon as possible. The execution of this plan will land three men on the moon and return them during the 3rd quarter of calendar year 1967, and will establish the Lunar Expedition in 1968. Completion of this plan will require the development of equipment, materials, and techniques to transport men to and from the lunar surface and to provide a lunar facility which will allow men to live and work in the extremely harsh lunar environment.

2.2 Lunex PROGRAM - DESCRIPTION

The Lunar Expedition Program is primarily concerned with the development of the equipment necessary to transport men and supplies to the lunar surface.

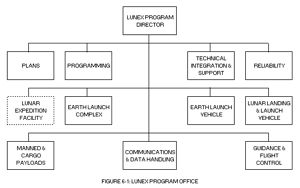

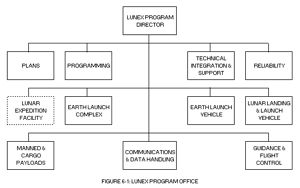

The key development in this program is the Lunar Transport Vehicle which is composed of the Space Launching System and either the Manned Lunar Payload or the Cargo Payload. The Manned Lunar Payload consists of a three-man Lunex Re-Entry Vehicle, a Lunar Launch Stage, and a Lunar Landing Stage. The same Lunar Landing Stage, plus a cargo package, composes the Cargo Payload. The relative effort required for the development of these two payloads in comparison with other portions of the complete Lunar Expedition Program is shown in Figure 2-1. A breakdown of the Lunar Transport Vehicle is shove in Figure 2-2.

The Space Launching System consists of a three-stage booster capable of placing either the Manned Lunar Payload or the Cargo Payload on a lunar intercept trajectory at escape velocity. This plan does not contain development information on the Launching System since such information is contained in a separate System Package Plan being prepared concurrently. The development schedules in these plans have been co-ordinated to insure compatibility.

In operation, the Manned Lunar Payload, weighing 134,000 pounds, will be boosted to escape velocity of approximately 37,000 ft/sec on a trajectory which intercepts the moon. Velocity will be sufficient to reach the moon in approximately 2 1/2 days. As the Manned Lunar Payload approaches the moon it is oriented with the local vertical by the use of horizon scanners. The Lunar Landing Stage decelerates the Manned Lunar Payload for a soft landing at a pre-selected site using an altitude sensing device to determine time of ignition. Landing at the pre-selected site will be accomplished using terminal guidance equipment and a prepositioned beacon to effect an offset landing.

The Lunar Launching Stage, using the Landing Stage as a base, will launch the Lunex Re-entry Vehicle on the return trajectory. In early test shots before men are included, the countdown and launch will be effected automatically by command from the earth. Small mid-course corrections may be necessary to insure re-entry into the earth's atmosphere within allowable corridor limits.

The Lunex Re-entry Vehicle will re-enter the earth's atmosphere within the allowable corridor so that it will not skip back into space again nor burn from excess heat. It will use aerodynamic braking to decelerate and will have sufficient lift capability to effect a normal unpowered aircraft landing at a base such as Edwards Air Force Base.

Several successful unmanned completely automatic flights of the type just described must be completed in order to establish confidence in the system reliability before manned missions will be attempted.

Cargo will be transported to the lunar surface using the same procedures and equipment except that the Lunar Launch Stage is not needed. The Cargo Package will have a weight equal to the combined weight of the Lunex Re-entry Vehicle and the Lunar Launch Stage.

As a separate approach to the problem of placing large payloads on the moon, techniques of rendezvous and assembly in earth orbit are being examined. Use of these techniques would require the launch, rendezvous and orbital assembly of sections of the Manned Lunar Payload and the Cargo Payload along with the required orbital launch booster and its fuel. The assembled vehicle would then be boosted from orbital velocity to escape velocity and would proceed as described above. Details of the major developments required such as rendezvous, docking and orbital assembly are outlined in a System Package Plan titled SAINT, being prepared concurrently. All programming information and schedules have been co-ordinated with this plan to insure compatibility and mutual support.

2.3 DESIGN PHILOSOPHY

The Lunar Expedition Plan has been oriented toward the development of a useful capability rather than the accomplishment of a difficult task on a one-time basis. The use of a large booster is favoured for the direct shot approach since studies have shown this to be more reliable, safer and more economical as well as having earlier availability. However, another approach using a smaller booster in conjunction with orbital rendezvous and assembly is also considered.

The manned Lunex Re-entry Vehicle is the key item in determining booster sizes. Its weight determines the size of the Lunar Launch Stage which in turn determined the size of the Lunar Landing Stage. The total weight of these three items is the amount that must be boosted to earth escape velocity by the Space Launching System. In this manner the size of the Space Launching System was determined.

A 2 1/2 day trajectory each way was selected as a conservative design objective. Longer flights would have more life support and guidance problems while shorter flights require higher boost velocity.

An abort capability will be included in the design insofar as possible. The next section describes the abort system in considerable detail.

Development and tests are scheduled on a high priority basis. Thus, the schedules shown in this plan are dictated by technological limitations and not by funds.

The entire program as described herein is an integrated program in that later development tests build on the results of early tests. Thus, equipment and techniques are proved out early, and confidence in the reliability is obtained by the time a man is included.

2.4 ABORT PHILOSOPHY

The insertion of a man into a space system creates a safety and reliability problem appreciably greater than the problem faced by any unmanned system. It is well recognised that maximum reliability is desirable, but also known that reliabilities in excess of 85 to 90% are extremely difficult to achieve with systems as complex as the Lunar Transportation System. Therefore, the need for an abort system to protect the man during the "unreliable" portions of the lunar mission is accepted.

A review of the proposed techniques and equipment to provide "full abort" capability has shown that due to payload limitations this is not practical during the early lunar missions. Thus a reasonable element of risk will be involved. In order to decrease this element of risk and to understand where it occurs the lunar mission has been divided into six time periods. These time periods are as follows:

a. Earth ascent.

b. Earth-moon transit.

c. Lunar terminal.

d. Lunar ascent.

e. Moon-earth transit.

f. Re-entry.

The development and test philosophy for this program is to launch the manned systems as early as possible in the program, but in an unmanned status. This will provide experience and allow the system to be checked out and "man-rated" before the first manned flight. It also means that the Lunex Re-entry Vehicle will be used for orbital and circumlunar flights prior to the lunar landing and return flight. The propulsion systems used for these early flights will be used throughout the program and the experience gained from each flight will increase the probability of success in reaching the final lunar landing and return objective. Also these propulsion systems will be used concurrently in other programs and at the time of man-rating will possess greater launch experience than can be expected for the largest booster of the Space Launching System. This would indicate that a larger number of unmanned flights should be scheduled for the larger full boost system than for the early nights. It also points out the need for a sophisticated Earth Ascent Abort capability during the first manned lunar landing and return flight.

In providing an abort philosophy for the Lunar Program it should be noted that the Lunar Re-entry Vehicle, the Lunar Landing Stage and the Lunar Launching Stage all possess inherent abort capability if utilised properly during an emergency. With sufficient velocity the re-entry vehicle is capable of appreciable manoeuvring and landing control to provide its own recovery system. The Lunar Launching and Lunar Landing Stages possess an appreciable delta-v capability that can be used to alter the payload trajectory to better accomplish recovery of the man. However, in either case the manoeuvres mill have to rely on computing techniques to select the best possible abort solution for any specific situation.

With this background, and with the understanding that in a future final design effort "full abort" may be required, the following abort design objectives for the Manned Lunar Payload are presented:

- Earth Ascent Phase

- On Pad - Full abort system will be provided.

- Lift-off to Flight Velocity for the Re-entry Vehicle - Full abort system will be provided.

- Flight Velocity for the Re-entry Vehicle to Escape Velocity - The basic Manned Lunar Payload will provide the abort capability.

- On Pad - Full abort system will be provided.

- Earth-Moon Transit

- Injection - Abort capability to compensate for injection error is desired as part of the basic Manned Lunar Payload. Computing, propulsion, etc., capabilities should be designed into the basic system to provide for the selection of the optimum abort trajectory.

- Mid-Course - Abort capability during Earth-Moon transit is desired for the Re-Entry Vehicle by means of a direct earth return, earth orbit, or circumlunar flight and earth return. Circumlunar flight generally requires the least, but the actual selection of the optimum trajectory should be accomplished when required by a computing capability, and executed by the Lunar Payload.

- Injection - Abort capability to compensate for injection error is desired as part of the basic Manned Lunar Payload. Computing, propulsion, etc., capabilities should be designed into the basic system to provide for the selection of the optimum abort trajectory.

- Lunar Terminal

This type of abort generally results from loss of propulsion or control of the Lunar Landing Stage. Where possible the Lunar Launching Stage will be used to attain a direct or circumlunar trajectory that terminates in an earth return. When this is not possible the Lunar Launching Stage will be used to accomplish the safest possible lunar landing. Recovery of the crew will not be provided in this system and selection of the above alternatives will be accomplished automatically on-board. Crew recovery will be provided by another stand-by Lunar Transport Vehicle.

- Lunar Ascent

Maximum inherent reliability by over-design of components and systems in the Lunar Launching Stage seems to be the most logical approach for this phase due to the extreme weight penalty imposed by a separate abort system.

The early missions will be faced with the highest risk, but as a facility on the lunar surface is developed, a rescue capability and the addition of an abort capability can be developed. No specific abort system will be provided for this phase, but consideration should be given to the possibility of future lunar modifications to provide for abort.

- Moon-Earth Transit

This would generally be associated with a gross trajectory error, or loss of control on re-entry. The only solution is to utilise the on-board capability that remains to achieve an earth orbit. After achieving orbit an earth-launched rescue mission would be initiated. This approach requires no additional abort system to be provided for this phase.

- Re-entry

Exceeding re-entry corridor limits, or loss of control could cause an emergency where abort would be desirable. Should sufficient delta-V remain from the over-design of the lunar launch stage, and not be used during Moon-Earth transit this would be used to attain an earth orbit where rescue could be achieved. No separate abort capability is required for this phase, but availability of propellant should be considered.

A detailed plan must be prepared for the complete Lunar Expedition operation. This plan must start from the first time man lands on the lunar surface and account for every single effort, or objective he is to accomplish during his stay on the surface. A crew of three men will be sent into a new and hostile environment where rescue or assistance from other human beings will be extremely difficult, if not impossible, for the first mission. Time will be at a premium and all items of equipment must be planned, designed and delivered in the Cargo Payloads so that they can be used in the easiest possible manner.

The procedures for first exploring the surface and then for constructing the expedition facility must all be derived, demonstrated and proven by earth operations prior to attempting the desired operation on the moon. An environmental facility that simulates the lunar surface with sufficient work area to test out equipment and procedures will be required.

Lunex Chart I - A Lunar Expedition Program Milestone Schedule |

The best photographic resolution to date is around one-half mile on the lunar surface, which provides adequate data for charts having a scale of 1:1,350,000. Good astronomical telescopes can be used to improve on the photographic data and obtain sufficient detail to prepare sectional charts like the one included. However, larger scale, accurate lunar charts will be required to complete detailed plans. Data can be obtained for such charts from a lunar orbiting photographic satellite which will provide sufficient resolution and overlap to enable stereographic compilation of contours and elevations. The NASA proposed Lunar Orbiter program is a possible source of the required data.

Planning for construction of the expedition facility can begin only after detailed surface information becomes available. Examination of returned lunar core samples will be necessary before plans can be completed.

SECTION III

MASTER SCHEDULES

3.0 INTRODUCTION

The establishment of the Lunar Expedition Program as a national objective will provide a worthy goal for the United States industrial and governmental organizations. The Lunar Expedition program has been based on extensive study, design, and research work during the past three years.

A Lunar Expedition program will require the use and centralised control of a major portion of the present military space capability. This will have the effect of giving the military program a scheduled long-range objective, and still provide useable military capabilities throughout the period. As an example, manned re-entry vehicles for orbital operations will be available in early 1965. They will be followed by a manned lunar re-entry vehicle in 1966.

Propulsion and Space Launching systems will be required to support the Lunex program. The program will set orbital and escape velocity payload requirements ranging from 20 to 350 thousand pounds in a 300 mile orbit and from 24,000 to 134,000 pounds at escape velocity. This capability will be obtained at an accelerated pace for the Lunex program and as a result the same capability will be available for military use much earlier than could be achieved if the start of the development programs had to be justified at this time entirely on the basis of military usefulness.

The accomplishment of the Lunex program will require maximum use of several presently programmed efforts and reorientation of others. The major program of direct interest to the Lunex are the SAINT and BOSS programs. Therefore, these efforts have been co-ordinated and integrated with the Lunex program. The BOSS shots will provide the necessary orbital primate test data to allow the manned life support package for the Lunex Re-entry Vehicle to be designed. The SAINT unmanned and manned program will provide additional orbital information on rendezvous, docking, and personnel and fuel transfer. In the event that the direct shot approach for the lunar expedition requires reorientation in future years to use orbital assembly techniques this capability will be available from the SAINT program.

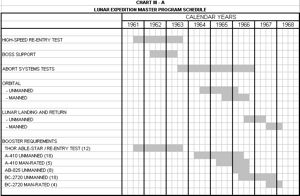

3.1 MASTER PROGRAM PHASING CHART

This schedule presents the integrated military program required to accomplish the Liner Expedition mission and to develop techniques for operating in the earth orbital and lunar arena. It was prepared to indicate the interface between this Lunar Expedition System Package Plan and the Space Launching system. The major national objective of this integrated program is to land men on the moon and return them in August of 1967.

3.2 LUNAR EXPEDITION PROGRAM SCHEDULE

This schedule presents the major items to be accomplished as a result of the Lunex program. The costing as shown on the schedule does not include the cost of developing the Space Launching System since this is provided under a separate System Package Plan. However, the cost of purchasing the flight vehicles is included.

The major "prestige" milestones of the program can be summarised as follows:

- First Manned Orbital Flight (3 Man Space Vehicle) - April 1965

- First Lunar Landing Cargo) - July 1966

- Manned Circumlunar Flight - Sept. 1966

- Manned Lunar Landing & Return - Aug. 1967

- Permanently Manned Lunar Expedition Jan. 1968

This schedule indicates the major Lunex program efforts required during fiscal years 1962 and 1963. The time allocation for management and Air Force technical evaluations have been kept to a minimum in order to meet the end objective of "man on the moon" in August 1967.

Several critical major decisions are required and are summarised below:

- Program Approval & Funding - July 1961

- Development-Production Funding - Dec. 1962

- Design Concept Decision - Jan. 1963

- Approval for Hardware Go-Ahead - Feb. 1963

3.4 LUNAR EXPEDITION TEST SCHEDULE

This schedule presents the major test items required for the Lunex program. Upon completion of the program, manned transport and unmanned cargo vehicles will be available to support the Lunar Expedition. The cargo vehicle will be capable of transporting approximately 45,000 pound "cargo packages" to the lunar surface for supporting the expedition. This same vehicle would be capable of transporting future military payloads to the lunar surface to support space military operations.

A detailed high-speed re-entry test program and an abort system test program is scheduled to provide basic re-entry data and to insure the safety of the men in the Lunex Re-entry Vehicle.

Prior to the first "manned lunar landing and return" flight, a series of test and check-out flights will be required. These will initially consist of orbital flights, and then very high altitude (50,000 miles or more) elliptical flights for testing the vehicles under re-entry conditions. When these have been completed, the first flights will be made around the moon (circumlunar) and return to an earth base. With a completely man-rated vehicle, and unmanned lunar landing flights completed, man will then make the first landing on the moon for the purpose of selecting a site for the Lunar Expedition Facility.

3.5 LUNEX SPACE LAUNCHING REQUIREMENTS

The purpose of this schedule is to summarise the space launching vehicle requirements and indicate when the launches will be needed.

The THOR-ABLE-STAR boosters will be used for the re-entry test program. The Space Launching System boosters designated as A, AB and BC, and solids as required, will be needed as indicated and their payload capabilities are estimated as follows:

Booster: Payload

A 410: 20,000 pounds (300 mile orbit)

AB 825: 87,000 pounds (300 mile orbit)

AB 825: 24,000 pounds (escape velocity)

BC 2720: 134,000 pounds (escape velocity)

3.6 PERSONNEL AND TRAINING

The Lunar Expedition program will require military personnel and a military training program. Details of this program are presented in Section IX and summarised on the Lunex Training Schedule included in this section.

The number of personnel required will increase from a limited staff in the early Program Office to a total of 6,000 personnel in the active expedition year. This total does not include "in plant" contractor personnel which is estimated to be on the order of 60 thousand.

Training of military personnel to meet the requirements of the Lunex program will be done by contractor and military training personnel. Maximum use will be made of program equipment when it can be scheduled for training purposes and in addition, allocation of production equipment is necessary to meet training requirements.

3.7 LUNEX CIVIL ENGINEERING FACILITIES SCHEDULE

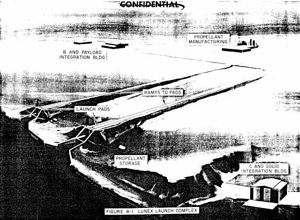

The facilities development and construction program is shown on this schedule. The first item to be accomplished is a site survey to determine the extent that the Lunex program can be supported by AMR and PMR. When this has been accomplished it will be possible to determine if the early Lunex test launches can be accomplished by using present facilities. Full consideration will be given to the possibility of building the Lunex Launch Complex as an expansion of the AMR or PMR. A more detailed presentation of the facilities program is contained in Section VIII, Civil Engineering.

DEVELOPMENT - TEST - PRODUCTION

4.0 INTRODUCTION

Implementation of the Lunar Expedition will require a completely integrated program involving the development, test, and production of items based on almost every known technical discipline. These technical disciplines are presently being investigated under a multitude of programs and organisations. The Lunar Expedition program will require these technical efforts to be immediately organised and re-oriented where necessary. This can best be accomplished by preparing a detailed development, test, and production program. When this program is completed each technical area can be evaluated by comparing its present program objectives and its required output to meet the Lunar Expedition program requirements. In the following paragraphs the Lunar Expedition development objectives and technical performance requirements are presented. The scope of the major existing technical programs and the necessary re-orientation is discussed.

4.1 DEVELOPMENT OBJECTIVES

4.1.1 HIGH SPEED RE-ENTRY

At the present time high-speed re-entry data in the velocity spectrum from 25,000 ft/sec to 45,000 ft/sec is non-existent. In order to meet the Lunex Re-entry Vehicle development schedule it will be necessary to have high-speed re-entry data during the engineering design program for the manned re-entry vehicle. Thus a compressed and co-ordinated test program for both ground test facilities and flight testing is necessary.

Immediate action is necessary to schedule and design the high-speed wind-tunnel test program. This will show the type of information that can only be achieved by means of flight testing.

The High-Speed Re-entry flight test program scheduled for the Lunex program is necessary to provide basic data on re-entry as well as to fly specific shapes in the later period of the test program. This selected shape program will be co-ordinated with the Lunex Re-entry Vehicle design effort.

In order to accomplish the High-Speed Re-entry flight test program it will be necessary to design and develop a test vehicle. This vehicle must use existing boost systems due to time limitations, but the payload will have to be designed especially for this program since none exists at this time. It is believed that the Atlas booster will prove adequate for these tests, but a decision must await the test payload design.

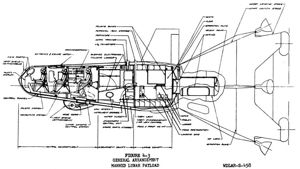

4.1.2 MANNED LUNAR PAYLOAD

The largest single development objective for the Lunex program is to provide a payload capable of transporting men and equipment to the lunar surface and returning them to a selected earth base. This payload would consist of a Lunar Landing Stage, Lunar Launch Stage and a 3-man Lunex Re-entry Vehicle.

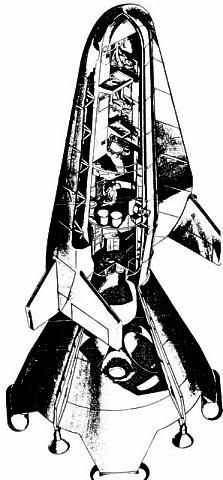

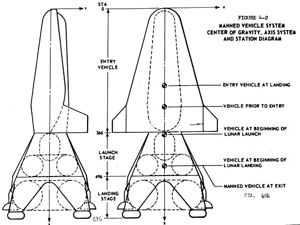

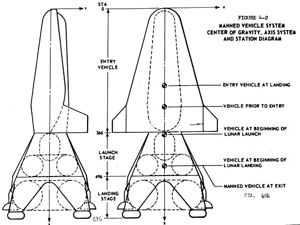

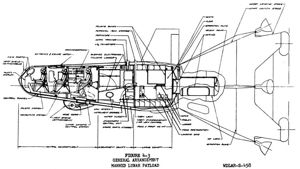

A typical Manned Lunar Payload is shown in a cut-away view in Figure 4-1. The characteristics and General Arrangement of the Manned Lunar Payload are seen in Figures 4-2 and 4-3. This payload is 52 feet 11 inches long, has the c.g. located 33 feet 8 inches from the nose of the re-entry vehicle and the interface diameter with the Space Launching System is 25 feet. The complete payload weighs 134,000 pounds at escape velocity, and a 20,205 pound Manned Re-entry Vehicle is returned to the earth.

The Lunex Re-entry Vehicle must be capable of entering the earth's atmosphere with a velocity of approximately 37,000 ft/sec. At the present time, basic re-entry information for velocities of this magnitude does not exist. Therefore, engineering design effort for this re-entry vehicle must be accomplished concurrently with other major sub-systems developments and integrated with the High-Speed Re-entry test program and the Abort System test and development program. This requires close management control of these programs by the Lunex Program Office.

Lunex Chart III-A Lunar Expedition Master Program Schedule |

The Lunar Landing Stage must be capable of landing the Lunar Launching Stage and the Lunex Re-entry Vehicle on the lunar surface. At the present time this is considered a difficult design problem because little is known about the lunar surface. Actually the best photographic resolution to date is approximately 1/2 mile. Many theories exist on the formation of the moon and therefore, the characteristics of its present surface. When these two factors are considered the only practical design approach is to provide an alighting system capable of landing on an extremely rough surface. An automatic levelling, orientation and launching system is required for system check-out prior to manned flight. Therefore, any assumption that the Manned Lunar Payload can be moved about on the lunar surface or that the payloads might initially transfer fuel on the lunar surface, might be entirely erroneous and jeopardise the complete Lunar Expedition effort. The landing stage will also have to be developed so that it is capable of landing the Cargo Payloads on the lunar surface.

The Lunar Launching Stage must be developed with a different philosophy than the previous sub-systems. First, it only operates in the vacuum of space and on the lunar surface. Secondly, it will be required to function after it has been located on the lunar surface for an extended period varying from several days to many months. Therefore, the stage must be developed to launch the re-entry vehicle after being subjected to a better vacuum then available in our best earth laboratory facilities, following possible temperature variations of 400 to 500 degrees, following possible meteorite bombardment and from a less than optimum launch angle. Specifically the stage development must consider propellant boil-off, automatic check-out, self-erection and remote (earth-moon) launching procedures.

The Lunar Launching Stage represents the major reliability problem of the system because an abort capability is planned for every phase of the Lunex mission except during launch from the lunar surface. During the early lunar flights an abort capability for this phase is just too expensive payload-wise for the Space Launching System. An abort capability during lunar launch essentially requires a duplicate lunar launching capability because the man must still be returned to the earth by either this system, or a special rescue flight. Therefore, until lunar support facilities are available, a separate system for abort during lunar launch does not seem practical. This creates the requirement to develop an extremely reliable Lunar Launching Stage.

4.1.3 CARGO PAYLOAD

The successful support of the Lunar Expedition will require a capability to deliver relatively large Cargo Packages to the lunar surface. These Cargo Packages will be soft landed at the desired lunar sites by the Lunar Landing Stage. Each Cargo Package will weigh approximately 45,000 pounds and will be specifically designed to carry the items desired to support the expedition. Development of the Cargo Payload and the specific packages will depend upon the Lunar Landing Stage design and the receipt of lunar environmental data. The actual design of the Lunar Expedition Facility will only be possible when detailed information on the lunar surface is available. Then, with the facility design information, the required materials, equipment, and procedures can be determined and a payload delivery sequence derived. The required payload delivery sequence is essential before the individual payloads can be designed and developed, but timely development of major items of equipment must proceed as their individual requirements become known.

4.1.4 ABORT SYSTEM

The philosophy of abort has been presented in the Program Description section of this document. The development of the abort equipment will require an integrated effort with the re-entry vehicle design and the test program must be conducted concurrently to provide a reliable and safe system for supporting manned operations.

It is essential that the re-entry vehicle development be conducted so that the life support capsule can also meet the requirement imposed by the abort system. Additional structural and propulsion items must be developed to provide for abort during the earth ascent phase of the lunar mission. The computing and control equipment on the Manned Lunar Payload must be capable of selecting the desired abort mode of operation and initiating the desired actions at the required time throughout the lunar mission.

4.1.5 SPACE LAUNCHING SYSTEM

The Lunar Expedition requires an extensive space launching capability. The development of this capability is a necessary part of the Lunex Program. At present this development is being included under the Space Launching System program. It is designed to support the low altitude test, orbital, circumlunar, and full lunar flights.

One of the major problems facing the design and development of the Lunex payloads with reference to the Space Launching System concerns the interface characteristics, trajectory considerations, and earth launch facilities.

The present prime interface characteristics for the Manned and Cargo Lunar Payloads are as follows:

- Interface Diameter - 300 inches

- Escape Payload Weight - 134,000 pounds

- Payload length - 635 inches

- Center of Gravity (Measured from top of payload) - 404 inches

| Payload Weight Pounds | Trajectory | Unmanned Flight | Manned Flight |

| 20,000 | 300 mile orbit | Aug 64 | April 65 |

| 87,000 | 300 mile orbit | Dec 65 | - - |

| 24,000 | Escape Velocity | Dec 65 | Aug 66 |

| 134,000 | Escape Velocity | July 66 | Aug 67 |

4.2 SUBSYSTEM DEVELOPMENT

The development of a manned lunar payload and a cargo package requires the development of subsystems and applied research in many technical areas. Studies have established that the advances in performance in these technical areas can be accomplished to meet the overall program schedulers and that no scientific breakthroughs are required. The important point is that items requiring development be identified, that necessary funds be allocated, and that effort be initiated without delay. The following sections discuss major subsystem requirements, present capabilities, and development required. Completed studies conducted by the Air Force and industry have established subsystem requirements in sufficient detail to outline development programs which should be initiated immediately. Present studies will refine these specifications further.

4.2.1 RE-ENTRY VEHICLE

4.2.1.1

The manned re-entry vehicle is a critical item in the development of the manned payload packages. This vehicle must be capable of returning from the moon and re-entering the earth's atmosphere at earth escape velocity (37,000 ft/sec). It must also have the capability of supporting three men on a 10-day round trip earth-moon mission. This mission would include boost from earth, coasting in earth orbit, ballistic flight to the moon, de-boost and landing on the moon's surface, remaining on the moon for one to five days, launch from the moon's surface, re-entering the earth's atmosphere and landing at a pre-selected base on the earth. Structural requirements imposed by inertial and pressure loading during boost, abort, trajectory correction, landing, re-entry, ground handling, and wind loading on the launch pad, have been considered in analysing desired vehicle characteristics. These studies have also included the heating and its effect on vehicle design as well as the effects of space and lunar environment including particles and radiation, meteorite penetration, and hard vacuum. Present design studies have estimated the total re-entry vehicle height at 20,205 pounds. The weight breakdown is as followers:

| a. Body | 7500 | |

| (1) Structure | 3500 | |

| (2) Heat Shield | 4000 | |

| b. Wing Group | 2000 | |

| (1) Structure | 800 | |

| (2) Heat Shield | 1200 | |

| c . Control System | 775 | |

| (1) Aerodynamic | 600 | |

| (2) Attitude | 175 | |

| d. Environmental Control | 1530 | |

| (1) Equipment Cooling | 138 | |

| (2) Structure Cooling | 940 | |

| (3 ) Cryogenic Storage | 452 | |

| e. Landing Gear | 700 | |

| f. Instruments & Displays | 200 | |

| g. Electric Power System | 600 | |

| h. Guidance & Navigation | 400 | |

| i. Communications | 250 | |

| j. Furnishings & Equipment | 850 | |

| (1) Seats & Restraints | 225 | |

| (2) Decompression Chamber | 175 | |

| (3) Equipment Compartment | 300 | |

| (4 ) Miscellaneous | 150 | |

| k. Life Support | 400 | |

| 1. Crew (3 men) | 600 | |

| m. Radiation | 1200 | |

| n. Abort System | 3000 |

Lunex Lunar Lander Lunex Project Manned Spacecraft |

Present re-entry and recovery techniques are outgrowths of the ballistic missile program utilising ballistic re-entry and parachute recovery. They are not compatible with the velocities associated with re-entry from the moon, with controlled landing, or with manned operations. Present engineering data associated with high speed re-entry is not adequate for vehicle design.

4.2.1.3

A development test program is required to obtain generalised data on re-entry phenomena and to test scale models of selected vehicle configurations so that final selection and design of an optimum vehicle can be made. Concurrently with this test program the projects within the applied research program will be directed so as to carry out the following investigations to provide necessary data for the Lunex Re-entry Vehicle Design.

4.2.1.3.1 AERODYNAMICS

(1) Study hypersonic low density aerodynamics including dissociation and ionisation, non-equilibrium flow phenomena, and the influence of radiation non-equilibrium on vehicle aerodynamic and heat transfer characteristics.

(2) Initiate an extensive ground based facility program directed at obtaining aerodynamic and heat transfer data up to Mach No. 25 (the maximum useable available capability). These tests would include the G.E. hypersonic shock tunnel in the M = 18 - 25 range; Cornell Aeronautical Laboratory hypersonic shock tunnel M = 12 - 18; Cornell Aeronautical Laboratory heated hydrogen hypersonic shock tunnel at M = 20; AEDC tunnel "B", "C", at M = 8 - 10; AEDC E-1 and E-2, M = 1.5 - 6; AEDC supersonic and subsonic facilities. This effort will be co-ordinated with the Lunex Engineering Design program and the High-Speed Re-entry test program.

(3) Correlation of wind tunnel tests in terms of prediction of free-flight vehicle performance characteristics in order to provide correlation between ground test facilities and free-flight vehicles.

(4) Complete vehicle static and dynamic stability analysis.

(5) Investigate local critical heat transfer problems including those associated with flaps and fins. The use of reaction controls, in order to alleviate critical heating areas, for vehicle stability and control, will be investigated.

4.2.1.3.2 MATERIALS

(1) Materials Development

(a) Low conductivity plastic material development

(2) Uniformly distributed low conductivity.

(2) Tailoring conductivity distribution in material in order to obtain high ablation performance at surface and low thermal conductivity in structure bond line.

(3) Develop materials with low ablative temperatures.

(4) Investigate bonding of materials to hot structure.

(b) Develop minimum shape change materials for aerodynamic control surface and leading edge applications. These materials will include pyrolytic graphite, alloys of pyrolytic graphite, and ceramics.

(2) Materials Analysis

(a) For selected materials above, develop analytical model to predict ablation performance and insulation thickness.

(b) Experimentally study material performance under simulated flight environments with the use of high enthalpy arc facilities (h/RT-0 = 700 to 800).

(c) Study the influence of space environment on selected materials. This will include the influence of vacuum, ultraviolet radiation, and high energy particles.

4.2.1.3.3 STRUCTURES

(1) Primary effort will be in the development of load-bearing radiating structures. For this structure, the following areas will be investigated.

(a) Thermal stress analysis and prediction.

(b) Dynamic buckling

(c) Strain gage applications to high temperatures.

(d) Experimental simulation on large scale structures of load temperature distribution, and history. The WADD Structures facility would be the one most appropriate to these tests.

4.1.2.3.4 DYNAMICS

(1) Analytical studies in the following areas should be undertaken.

(a) Unsteady aerodynamic forces at hypersonic speeds.

(b) Aeroelastic changes in structural loading and aerodynamic stability derivatives.

(c) Flutter

(d) Servoelastic coupling with guidance system.

(e) Fatigue due to random loading.

(f) Transient dynamic loading.

4.2.1.4

Present projects within the Air Force applied research program will be reviewed and reoriented or effort increased, as appropriate, to provide the necessary data. Projects which can be used for this purpose are listed below:

6173 (U) Study of Controlled Final Deceleration Stages for Recoverable Vehicles.

1315 (U) Bearings and Mechanical Control Systems for Flight Vehicles.

1368 (U) Construction Techniques and Applications of New Materials.

1370 (U) Dynamic Problems in Flight Vehicles.

1395 (U) Flight Vehicle Design.

6146 (U) Flight Vehicle Environmental Control.

1309 (U) Flight Vehicle Environmental Investigation.

6065 (U) Performance and Designed Deployable Aerodynamic Decelerations

4.13

4.2.1.5 In addition to the applied research efforts referred to in Paragraph 4.2.1.4 an intensive study of re-entry vehicle characteristics required for the Lunex mission is being accomplished under project 7990 task 17532. This study will define an optimum vehicle configuration and present the most feasible technical approaches to solving the various re-entry problems. For example, the desirability of ablative and/or radiation techniques for cooling will be determined.

4.2.2 PROPULSION

4.2.2.1

The Manned Lunar Payload requires a booster capable of placing a 134,000 pound package at escape velocity on a selected lunar trajectory. This booster development has been included in the Space Launching System Package Plan and its development will be done for the Lunex program.

4.2.2.2

Propulsion systems for the Manned Lunar Payload which will be developed under this plan are those required for the following operations:

Lunar Landing

Lunar Launch

Trajectory correction

Attitude control

Abort

4.2.2.3

The Lunar Lending Stage must be capable of soft landing at approximately 20 ft/sec a 50,000 pound payload on the moon. This payload consists of the Lunar Launching Stage and Lunex Re-entry Vehicle. Preliminary design data from studies completed to date show that the manned re-entry vehicle will weigh approximately 20,000 pounds and a launch stage of 30,000 pounds will be required. Similar estimates for the Lunar Landing Stage indicate that it will weigh 85,000 pounds. During lunar landing, if an initial thrust to weight ratio of 0.45 is assumed as consistent with the deceleration desired and time of deboost, an initial retro thrust of 60,000 pounds is required. At final touchdown on the moon, with all delta-v cancelled and assuming essentially all de-boost propellant consumed, approximately 10,000 pounds of thrust is required. Some throttling or gimballing of the engine may be required at the 10,000 pound level to reduce the axial component of thrust. The requirements on the landing engine are for a 60,000 pound engine with a 6 to 1 throttling ratio, or a cluster of four engines of 15,000 pounds thrust and at least one with a throttling range of 1.5 to 1. Assuming a thrust to weight ratio of 1.5 (Moon weight) for the Lunar Launch Stage, a 12,000 pound thrust engine is required for lunar launch. An engine of the LR-115 type will meet these requirements with some development. Minor development will be necessary if the range of throttleability is 20 to 30%. If the range of thrust control is 50% or greater, a more extensive program will be required.

4.2.2.4

In addition to the deboost and launch, it is necessary to provide a trajectory and attitude control propulsion capability. A velocity capability of 300 to 1200 ft/sec will be required for trajectory corrections during midcourse, lunar landing and return. Attitude control will be required during lunar landing and launch, and midcourse, with specific methods to be determined by optimisation studies during vehicle design. There do not appear to be any major development problems to be overcome to provide trajectory correction or attitude control capability.

4.2.2.5

An abort system to provide safe removal of the crew in the event of failure before, or during launch must be developed. A propulsion system with an extremely short reaction time is necessary to insure safe crew removal.

4.2.2.6

Specific engine sizing, throttleability requirements, propellant and oxidizer selection, nozzle type, etc., will be determined upon completion of a preliminary design in which such tradeoff comparisons as range of throttling versus use of verniers will be made and optimized selections made. Development work will be initiated within present projects in the Air Force applied research program to raise the level of technology in areas such as throttleability. Projects which can be utilized for this purpose are:

3085 (U) Liquid Rocket Engine Technology

3148 (U) Development of Liquid and Solid Rocket Propellants

6753 (U) Rocket Propulsion Subsystems

6950 (U) Propulsion Attitude Testing

4.2.3 LIFE SUPPORT

4.2.3.1

The life support package for the manned Lunar Payload will be required to function for a minimum of 10 days. This is based on the premise that a one-way trip to the moon will require 2 1/2 days, and the stay on the lunar surface will be on the order of 5 days. The life support systems must be capable of supporting three men during high acceleration boost, approximately 2 1/2 days of weightlessness, one to five days of 1/6 earth weight, 2 1/2 days of weightlessness, re-entry deceleration and return to full earth gravity. At the same time it must provide a shirtsleeve cabin environment under the space and lunar environments, including extreme temperature gradients, absence of oxygen, radiation, etc.

4.2.3.2

Studies of the life support system weight requirements indicate that the life support package can be provided within the weight allocation for the 20,000 pound Lunex Re-entry Vehicle. The life support system weight analysis was based on physiological experiments under simulated apace flight conditions such as confinement, special diets, reduced pressure, etc. At the present time approximately 65 to 70 percent of the knowledge required to design the three man package is available. However, to obtain the additional data experimental laboratory and flight testing is required. Most information is presently obtained by piggyback testing aboard experimental vehicles, but to support the Lunex program and to meet the desired schedules the BOSS primate program must be initiated and adequately supported.

4.2.3.3

Most of the data available today consists of physiological support (nutrition, breathing oxygen, pressure suits, and restraints for limited periods), but there is a lack of knowledge on prolonged weightlessness and the biological effects of exposure to prolonged space radiation. The BOSS program initially will support a chimpanzee for periods up to 15 days and has been programmed to provide a life support package of sufficient size and sophistication to support a man. Thus, with the BOSS program the data will become available so that the Lunex program can design and construct the life support package as required for April 1965.

4.2.3.4

Throughout this development all life support knowledge and techniques will be fully exploited. Techniques learned in the work with the Discoverer package were utilised in building the Mercury package. In turn, experience and knowledge gained from Mercury is being fully exploited in the development of the present BOSS package .

4.2.3.5

The life support program (BOSS) is vital to meet the objectives of the Lunex program. However, other AFSC programs must be considered for possible application to Lunex and the following are now being evaluated:

6373 (V) Aerospace Life Support

7930 (U) Bio-Astronautlcs

4.18

4.2.4 FLIGHT VEHICLE POWER

4.2.4.1

Electrical power will be required to operate the Lunex Re-entry Vehicle subsystems such as life support, navigation and guidance, instrumentation, and communications. The power requirement for there subsystems, has been analysed and determined to he approximately 3 kW average during a ten-day manned trip to the moon and return. Peak power requirement will be approximately 6 kW.

4.2.4.2

Solar, nuclear, and chemical powered systems were evaluated against these requirements. While all of these systems may be capable of meeting these requirements the chemically powered systems have been selected for early adaptation into the program. Specifically, fuel cells and turbines, or positive displacement engines appear to offer the moat advantageous solution. The final selection will be made during the final re-entry vehicle design when a detailed analysis of the trade-off between various available systems considering relative weight, efficiency, reliability, and growth potential is available. The optimum system may be a combination of fuel cells and chemical dynamic systems with one system specifically designed to supply peak demand. With this approach the system to provide peak load capacity, will also provide backup power in the case of equipment malfunction during a large part of the mission. A battery supply may be used to furnish emergency power required for crew safety during critical periods in the flight.

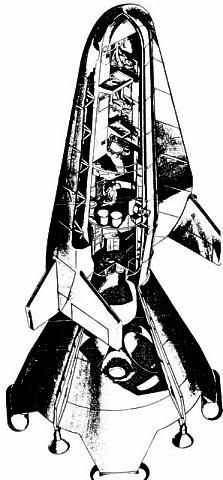

Lunex Lunar Lander Two view drawing of Lunex Lunar Lander, showing centre of gravity and coordinate system stations. |

Present level of technology is such that a satisfactory flight vehicle power system will be available when required for the Lunex mission. Additional development effort should be initiated in certain specific areas, such as a reliability evaluation program for fuel cells and an investigation of the problems of operating chemical dynamic systems in the zero G environment.

Close co-ordination must also be maintained with the manager of project 3145 (U) Energy Conversion, to insure the availability of the required secondary power sources.

4.2.5 GUIDANCE AND CONTROL SYSTEM

4.2.5.1

A study of the guidance and control requirement for the lunar vehicle indicates that the mission can be accomplished by reasonable extensions of present state-of-the-art equipment. The complete lunar vehicle guidance package should be capable of furnishing guidance and control during the following phases of the lunar mission.

Ascent and Injection

Outbound Mid-course

Lunar Landing

Lunar Ascent

Inbound Mid-course

Earth Re-entry

Earth Landing

Present state-of-the-art equipment is capable of handling portions of the guidance and control problem associated with the above phases of flight. However, in order to obtain a complete guidance and control system, it is felt that development of the following items should be undertaken.

4.2.5.2 INERTIAL PLATFORM

Guidance requirements for both the manned and unmanned vehicles can be met with the use of guidance concepts based on the use of inertial and corrected inertial data in a combination of explicit and perturbation computations of present and predicted trajectories. Consequently, an inertial platform configuration suited to the space environment is needed. This platform should be light in weight, highly reliable, and capable of maintaining a space-fixed reference over a long interval of time. Present gyroscopic devices and accelerometers are neither accurate nor reliable enough to accomplish the space mission.

An inertial platform which holds great promise for use in lunar missions is one utilising electrically suspended gyros in conjunction with advanced accelerometers capable of operating in a space environment. Present electrically suspended gyros are capable of operating with a drift rate of .0005 deg/hr/g and it is anticipated that by 1966, a drift rate of .0001 deg/hr/g will be attainable. Also, no difficulties are foreseen in maintaining suspension of the rotating member in an acceleration field of 15 G's with 30 g's being possible. Development of a small inertial platform utilising electrically suspended gyros will be required for the lunar mission.

4.2.5.3 STAR TRACKER

In order to increase the reliability and the accuracy of the inertial platform, a compact star tracker for use with the platform during the outbound and inbound mid-course phases of the lunar flight is desired. Also, the star tracker should be capable of operating in a lunar environment so that it can be used for stellar alignment during the lunar launch portion of the mission. The accuracy of present solid state star trackers is approximately 10 seconds of arc and their weight is approximately 15 pounds. However, these trackers are untested in a space environment and must be developed for the lunar mission and for use with the small inertial platform. In particular, the star tracker must be capable of furnishing accurate stellar alignment information to the inertial platform during the lunar ascent portion of the mission. If it is possible to develop a controllable thrust engine in time to meet the launch schedule, the boost and injection guidance problem for the lunar ascent will be simplified as it will be possible to time-control a predetermined velocity path. This development could possibly reduce the accuracy requirement of the star tracker.

4.2.5.4 LONG BASELINE RADIO NAVIGATION

Since manned as well as unmanned flights are planned for the lunar mission, it is necessary to have a navigation system to back-up the inertial system and to increase the over-all accuracy of the guidance and control techniques. Long baseline radio/radar tracking and guidance techniques offer great possibilities for tracking and guiding vehicles in cislunar apace. Present studies show that there are a number of problems yet to be solved to give the long baseline radio navigation the desired accuracy. Among these problems are 1) the accuracy with which co-ordinates can be determined for each tracking station, 2) the accuracy with which corrections can be made for tropospheric and ionospheric propagation effects on the system measurements, and 3) the accuracy with which "clocks" can be synchronised at the several stations. Reasonable extensions of the state-of-the-art should be able to overcame these problems however, and it is felt that the development of a long baseline radio navigation system will be necessary for the lunar mission.

4.2.5.5 DOPPLER RADAR

Anticipation that radio beacons will be in place on the lunar surface has somewhat simplified the lunar landing phase of the mission. The use of mid-course guidance will enable the vehicle to approach the moon within line-of-sight of at least one of the radio beacons, and the beacon can be utilised for the approach phase of the lunar landing. However, for final vertical velocity measurement, a sensing technique particularly sensitive to small velocity changes is required. A small CW Doppler radar is ideally suited for this requirement. Therefore development of a small, reliable Doppler radar which can operate in the lunar environment is needed. In order to decrease the power requirement for the radar it should not be required to operate at a range of over 300 miles.

4.2.5.6 RE-ENTRY GUIDANCE

Major emphasis must be placed on the guidance requirements for the re-entry phase of the lunar mission. Position, velocity, and attitude can be measured by the inertial system, however, other measurements initially required will be temperature, temperature rate, structural loading and air density. Extensive further study is needed to define these measurements with any accuracy. Early earth return equipment should furnish the data necessary to develop the required re-entry guidance package for the lunar mission.

4.2.5.7 ADAPTIVE AUTOPILOT

The control of the re-entry vehicle mill require an adaptive autopilot due to the wide variation in surface effectiveness. Adaptive autopilots such as used in the X-15 are available, but extensive development is needed to ready them for use in the lunar mission.

4.2.5.8

The following projects or specific tasks within these projects can be utilised to provide the development required for the Lunex program.

4144 (U) Guidance and Sensing Techniques for Advanced Vehicles

40165 (U) Data Conversion Techniques

50845 (U) Guidance Utilising Stable Timing Oscillators

50899 (U) Molecular Amplification Techniques

4427 (U) Self-Contained Electromagnetic Techniques for Space Navigation

4431 (U) Inertial System Components

44169-II (U) Space Adapted Celestial Tracking System

44169-III (U) Multi-Headed Solid State Celestial Tracker

44169-IV (U) Solid State Celestial Body Sensors

5201 (U) Inertial Systems Technique

5215 (U) Military Lunar Vehicle Guidance

50820 (U) Military Lunar Vehicle Guidance Systems

58821 (U) Military Lunar Vehicle Terminal Guidance

4.2.6 COMPUTER

4.2.6.1

The United States has the ability to provide a suitable computer facility at the present time to support the Lunex mission. As the milestones in the program are realised and requirements become more complex, the computer capability will improve to meet these more stringent requirements. Detailed studies on the specific needs of the missions, time-phased, will be conducted to determine trade-offs among possible techniques to insure that machine sophistication does not became an end unto itself. The following guidelines providing adequate flexibility, have been followed in arriving at the required development recommendations:

a. Manned vehicles will require extensive data reduction to give an operator real-time displays of the conditions around him and solutions to problems such as, velocity and attitude corrections, etc.

b. Sensor control (aiming and sampling rate) and data processing will be accomplished on the vehicle either on ground command, or by operator direction.

c. Mid-course and terminal guidance requirements will make severe demands upon vehicle-borne computational systems.

d. Radiation hazards and effects which are unknown at present could influence the technology that will be utilised for lunar missions.

e. Emergency procedures must be available in the event that the operators became incapacitated and incapable of returning to earth at any time during the mission.

4.2.6.2

The computer capability can be expanded in two basic ways by improved hardware, or new concepts. Examples of new approaches which will be reviewed prior to selection of the final vehicle design are the following:

a. Standardised computer functions incorporated into modules so that they can be used to "build" their capability for each mission required. Such a concept would allow a vehicle designer to fabricate a computational facility without resorting to extensive redesign and/or re-packaging. The modularised concept noted above is particularly adapted to unmanned missions.

b. For a manned mission two fixed programs could be permanently placed in storage; these would be an overall command, or executive routine to direct the sequences of operation, and the other could be an emergency return-to-earth routine that could be actuated by the master control. Thus a 5-pound tape unit would replace a larger core memory and provide a higher degree of flexibility. The principal advantage in this system is that the computer is general-purpose in design and therefore useable on a large variety of missions and unnecessary capabilities will not be carried on a particular mission.

c. An optimised hybrid of analogue and digital devices combined to use the better features of each, i.e., speed of problem solution from the analogue and precision, flexibility, and data reduction from the digital.

4.2.6.3

Substantial improvements in computer capability, developments, reliability, volume, weight, and power consumption will be available for the Lunex program by effort expended in the following areas:

a. Core-rope memories to be used in fixed memory applications.

b. Functional molecular blocks. By 1963, the date of earth orbit, it is expected that more than 80% of all computer functions can be performed by this method. Advantages are numerous: high memory densities, extremely small size, small weight and power consumption.

c. Self-healing, or adaptive programming techniques as a means for back-up on component reliability.

d. Electroluminescent-photoconductive memory devices should be considered for their radiation and magnetic invulnerability. In this regard, pneumatic bistable elements should be considered for the same reason.

e. Photochromic storage devices have advantages in high storage densities, 1 billion bits/cubic inch. Certain applications, such as semi-permanent storage, could benefit from this feature.

4.2.6.4

The following projects in the Applied Research Area will be utilised to obtain improvement in computer technology:

3176 (U) Space Borne Computation & Control Techniques

4421 (U) Digital Computation Methods & Techniques

DEVELOPMENT - TEST - PRODUCTION

4.2.7 COMMUNICATIONS

4.2.7.1

The manned lunar mission will require communications channels between the vehicles and earth and on the lunar surface for telemetry, T.V., voice, and vehicle control. Specific system parameters will depend on the characteristics of the ground tracking network and communications stations which will be used to support the lunar missions.

Figure 4-3 Inboard Profile of Lunex Spacecraft |

There are no significant technical problems associated with the development of equipment to perform the required communications operations. One exception to this general statement is that during re-entry radio transmission may not be possible at the lower frequencies utilised elsewhere in the mission because of the plasma shield set up by aerodynamic heating. One possible solution may be to provide a separate system operating at 10,000 mcs for re-entry. Overall savings in equipment weight, and power requirements will result from careful analysts and identification of requirements for information transfer and maximum utilisation of system components in a dual role. This will be done during the vehicle design phase. While not a requirement for early missions the capability to provide a secure communications link is desirable and will be considered during final design of the communications systems. A secure communications link will be a requirement in later missions. Throughout all phases, communications links critical to mission success should incorporate a high degree of protection against natural or man-made interference, or deliberate jamming.

4.2.7.3

The following Air Force projects will be reviewed and used to provide the necessary results required for the Lunex mission:

4335 (U) Applied Communications Research for Air Force Vehicles

4519 (U) Surface & Long Range Communications Techniques

5570 (U) Communications Security Applied Research

4.2.8 ENVIRONMENTAL DATA

4.2.8.1

Present knowledge of the lunar environment is extremely limited and it is necessary to obtain detailed information concerning the lunar composition, subsurface structure, surface characteristics, meteorite flux, level of solar and cosmic radiation, and magnetic field. This knowledge is required to design the equipment for the Lunex program so that personnel may be protected and the mission accomplished.

4.2.8.2

The importance of lunar composition in manned exploration of the moon lies largely in the ability of the moon to provide fuel for vehicles and secondary power, as well as to supplement life support systems with additional water, radiation shielding material, and semi-permanent shelters. Of these lunar resources, water appears to be of major importance both as a fuel and in life support. Water will probably be present both as ice in permanently shadowed zones and as water of hydration in certain minerals such as serpentine.

4.2.8.3

Present knowledge of lunar composition is almost entirely theoretical. The relatively low lunar density (3.34) indicates low metal content. By analogy with the compositions of meteorites it is generally assumed that the moon is composed of chondritic (stony meteorite) material. That this assumption is only partially valid is demonstrated by the fact that chondritic meteorites would have to lose about 10% of their iron content in order to attain this lunar density.

4.2.8.4

The Air Force and NASA are presently trying to determine the lunar composition indirectly through study of tektites, which may be fragments of the moon, and through study of micrometeoritic dust captured above the atmosphere. (Air Force efforts are funded under Project 7698).

4.2.8.5

The Air Force is trying to determine the lunar composition directly by means of spectrometric analysis of the natural X-ray fluorescence of the moon due to the bombardment of the lunar surface by solar radiation. The first knowledge of lunar composition is anticipated in March of 1962. (This work is also funded under Project 7698).

4.2.8.6

NASA intends to measure the lunar composition directly by means of its Surveyor lunar probe now scheduled for mid-1963.

4.2.8.7