Home - Search - Browse - Alphabetic Index: 0- 1- 2- 3- 4- 5- 6- 7- 8- 9

A- B- C- D- E- F- G- H- I- J- K- L- M- N- O- P- Q- R- S- T- U- V- W- X- Y- Z

Astrobee

Astrobee 200 |

Status: Retired 1983.

From Aerojet - The Creative Company, 1995:

By 1969 it appeared that there was a substantial need for small and extremely low cost sounding rockets, and enough experience had been gained that a dual thrust motor would be attractive. As a result the NASA Office of Aeronautics and Space Technology (NASA-OAST) funded the development of such a motor and vehicle. The resulting Astrobee D motor (and complete vehicle of the same name) was 6" in diameter and had a thrust in the boost phase of about 3600 lbf, and 2000 lbf in the sustainer mode. Sixty five were produced, and 49 were flown, with one failure.While this program was in process, NASA Goddard Space Flight Center authorized a much larger version (15" diameter) having thrust levels of 38,000 lbf boost and 8,000 lbf sustain, which was designated the Astrobee F. The first firing test in December 1970 resulted in meeting the desired propulsion parameters, including a duration of 50 seconds. However the nozzle suffered asymmetric erosion that removed one quadrant of the insulation. The second test resulted in chamber burnout close to this same location, and it took two more iterations to achieve a successful design. The Astrobee F was designed specifically to approximate the very mild flight environment of the Aerobee in terms of wind sensitivity, dynamic pressure, aerodynamic heating and stability margin - and it met these goals. Flight tests were successful, and 48 units were flown, but again suffered one failure of the rocket motor.

Although Space General Corporation fielded several other vehicles designated as Astrobees, none of these used any dual thrust Aerojet solid propellant motors. These included Astrobee 200, 250, and 1500.

Astrobee is a family of sounding rockets that is in the tradition of the Aerobee family. The Astrobee rocket uses a solid propellant second stage where the Aerobee has a liquid one. Astrobees are a family of four, ranging from the tiny 10 ft long Astrobee D to the 48 ft high Astrobee Super Chief II and III. The name Chief was selected by the Navy in the same tradition as the Army Corporal and Sergeant rockets. The middle range Astrobee F is comparable in performance to Aerobee 170. But the Astrobee 1500 has about three to four times the altitude capability of the largest Aerobee - the 350. The Super Chief III Astrobee has up to 60% more payload than the Aerobee 350. The largest Astrobees are 31 in. diameter compared to the 15 in. and 22 in. diameters of the Aerobees. This 31 in. diameter is quite large for a sounding rocket and quite respectable for any rocket when considering that the small ICBM is 46 in. diameter and Minuteman III is 52 inches. The largest Astrobee is also nearly 10% longer than the Trident II SLBM

The D, F and 1500 models use an aerodynamic fin-stabilized first stage and a spin-stabilized second stage. Both stages of the Super Chief are fin-stabilized. Most motors are built by Aerojet and include Aerojet Jr., ALCOR, and Astrobee motors. They mostly use Hydroxyl Terminated Polybutadiene (HTPB) for the required environmental characteristics and the ability to produce the slender designs peculiar to sounding rocket sustainer motors. It also gives high Isp at the very low propellant burning rates needed for these motors. Dual thrust was designed into the motors to limit the wind dispersion by use of high initial acceleration without auxiliary boosters. The sustainer thrust is about one-fourth the booster thrust to limit aerodynamic loading to Aerobee levels. The Astrobee Super Chief used a Talos booster motor with over 115,000 lbf average thrust on the first stage. Either a Sergeant or Castor motor were used on the second stage with burn durations of up to 40 seconds. The Astrobees would sometimes compete with the more expensive but longer duration and earth-circling satellites. The Astrobee 1500 could generally go higher than most satellites and certainly cost less. Practical size payloads could be lifted to 700 to 1,600 miles altitude.

Astrobee design stressed reliability and low cost. Reed Jenkins remembers, "They had elegant simplicity. The motor was only four parts, including a one-piece nozzle. We had to keep the cost down and it was a constant battle." Launch configurations were oriented to low cost and also quick turnaround. The limit of two stages allowed units to be readily trailered. Assembly was made at ground level like the Aerobees and the launcher would erect the vehicle to the vertical launch position. The Super Chief needed very substantial launchers, yet there were several to choose from, including one adapted from a ship's 5 inch gun turret mount, the Athena launcher and the AML-20K launcher.

The flight logs maintained by Al Olson show there were 309 successful Astrobee flights of 314 post-development flights yielding a reliability of 98.4%. This is an enviable record for any multi-stage rocket launch vehicle.

More at: Astrobee.

| Astrobee 1500 American sounding rocket. Three stage vehicle consisting of 2 x Recruit + 1 x Aerojet Jr + 1 x Alcor |

| Astrobee 200 American sounding rocket. Two stage vehicle consisting of 1 x Genie + 1 x Alcor |

| Astrobee 500 American sounding rocket. Three stage vehicle consisting of 1 x Genie + 1 x Alcor + 1 x Asp |

| Astrobee D American sounding rocket. Single stage vehicle. |

| Astrobee F American sounding rocket. Single stage solid-fueled dual-thrust rocket replacement for the Aerobee 150. |

Country: USA. Launch Vehicles: Astrobee 500, Astrobee 1500, Astrobee 200, Astrobee D, Astrobee F. Launch Sites: Wallops Island, White Sands, Vandenberg, Poker Flat, Fort Churchill, Eglin, San Marco, Red Lake. Agency: Aerojet. Bibliography: 2, 7603.

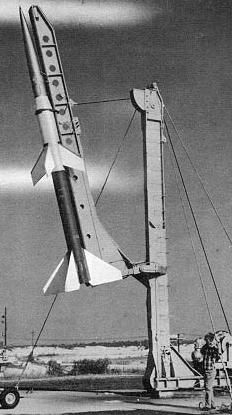

| Astrobee F Credit: via Andreas Parsch |

1960 March 22 - . Launch Site: Eglin. LV Family: Astrobee. Launch Vehicle: Astrobee 500. FAILURE: Failure.

1961 March 8 - . 17:53 GMT - . Launch Site: Eglin. LV Family: Astrobee. Launch Vehicle: Astrobee 1500.

1961 June 30 - . 17:20 GMT - . Launch Site: Eglin. LV Family: Astrobee. Launch Vehicle: Astrobee 200. FAILURE: Failure.

1961 August 1 - . 20:18 GMT - . Launch Site: Vandenberg. Launch Complex: Vandenberg LC-A. LV Family: Astrobee. Launch Vehicle: Astrobee 1500. FAILURE: Failure.

1961 December 8 - . Launch Site: Vandenberg. Launch Complex: Vandenberg LC-A. LV Family: Astrobee. Launch Vehicle: Astrobee 1500.

1962 January 29 - . 20:00 GMT - . Launch Site: Eglin. LV Family: Astrobee. Launch Vehicle: Astrobee 200.

1962 April 18 - . 19:32 GMT - . Launch Site: Eglin. LV Family: Astrobee. Launch Vehicle: Astrobee 200.

1962 April 30 - . 18:35 GMT - . Launch Site: Eglin. LV Family: Astrobee. Launch Vehicle: Astrobee 200.

1962 July 9 - . Launch Site: Vandenberg. Launch Complex: Vandenberg LC-B. LV Family: Astrobee. Launch Vehicle: Astrobee 1500. FAILURE: Failure.

1963 April 8 - . 11:26 GMT - . Launch Site: Wallops Island. Launch Complex: Wallops Island LA2. Launch Pad: LA2A. LV Family: Astrobee. Launch Vehicle: Astrobee 1500. FAILURE: Failure.

- Test mission - . Nation: USA. Agency: NASA Greenbelt. Apogee: 72 km (44 mi).

1963 December 9 - . 05:24 GMT - . Launch Site: Fort Churchill. LV Family: Astrobee. Launch Vehicle: Astrobee 200. FAILURE: Failure.

- Ionization detector Aeronomy / aurora mission - . Nation: USA. Agency: USAF. Apogee: 242 km (150 mi).

1964 June 10 - . 05:03 GMT - . Launch Site: Vandenberg. LV Family: Astrobee. Launch Vehicle: Astrobee 200.

1964 July 18 - . 12:22 GMT - . Launch Site: Fort Churchill. LV Family: Astrobee. Launch Vehicle: Astrobee 200.

1964 October 21 - . 19:44 GMT - . Launch Site: Wallops Island. Launch Complex: Wallops Island LA2. Launch Pad: LA2A. LV Family: Astrobee. Launch Vehicle: Astrobee 1500.

1966 January 23 - . 06:06 GMT - . Launch Site: Fort Churchill. LV Family: Astrobee. Launch Vehicle: Astrobee 200.

- Electron flux Ionosphere / aurora mission - . Nation: USA. Agency: USAF CRL. Apogee: 301 km (187 mi).

1966 January 28 - . 06:43 GMT - . Launch Site: Fort Churchill. LV Family: Astrobee. Launch Vehicle: Astrobee 200. FAILURE: Failure.

1966 December 14 - . 08:16 GMT - . Launch Site: Fort Churchill. LV Family: Astrobee. Launch Vehicle: Astrobee 200.

- AE15.735 electron flux Chemical release / aurora mission - . Nation: USA. Agency: USAF. Apogee: 212 km (131 mi).

1967 February 25 - . 02:35 GMT - . Launch Site: Wallops Island. Launch Complex: Wallops Island LA2. Launch Pad: LA2A?. LV Family: Astrobee. Launch Vehicle: Astrobee 1500.

1967 August 30 - . Launch Site: Wallops Island. Launch Complex: Wallops Island LA2. Launch Pad: LA2A?. LV Family: Astrobee. Launch Vehicle: Astrobee 1500.

1968 April 20 - . 17:38 GMT - . Launch Site: Wallops Island. Launch Complex: Wallops Island LA2. Launch Pad: LA2A?. LV Family: Astrobee. Launch Vehicle: Astrobee 1500.

1969 October 15 - . 22:43 GMT - . Launch Site: Wallops Island. Launch Complex: Wallops Island LA2. Launch Pad: LA2A?. LV Family: Astrobee. Launch Vehicle: Astrobee 1500.

1970 June 8 - . Launch Site: White Sands. LV Family: Astrobee. Launch Vehicle: Astrobee D.

1970 June 8 - . Launch Site: White Sands. LV Family: Astrobee. Launch Vehicle: Astrobee D.

1971 January 19 - . 19:43 GMT - . Launch Site: Wallops Island. LV Family: Astrobee. Launch Vehicle: Astrobee D.

1971 January 21 - . 18:18 GMT - . Launch Site: Wallops Island. LV Family: Astrobee. Launch Vehicle: Astrobee D.

1971 January 21 - . 19:02 GMT - . Launch Site: Wallops Island. LV Family: Astrobee. Launch Vehicle: Astrobee D.

1971 January 21 - . 19:38 GMT - . Launch Site: Wallops Island. LV Family: Astrobee. Launch Vehicle: Astrobee D.

1971 January 21 - . 20:19 GMT - . Launch Site: Wallops Island. LV Family: Astrobee. Launch Vehicle: Astrobee D.

1971 January 21 - . 21:02 GMT - . Launch Site: Wallops Island. LV Family: Astrobee. Launch Vehicle: Astrobee D.

1972 January 28 - . 21:08 GMT - . Launch Site: White Sands. LV Family: Astrobee. Launch Vehicle: Astrobee D.

1972 January 29 - . 05:00 GMT - . Launch Site: White Sands. LV Family: Astrobee. Launch Vehicle: Astrobee D.

1972 March 6 - . 12:14 GMT - . Launch Site: Poker Flat. LV Family: Astrobee. Launch Vehicle: Astrobee D.

1972 March 9 - . 10:52 GMT - . Launch Site: Poker Flat. LV Family: Astrobee. Launch Vehicle: Astrobee D.

1972 September 26 - . 18:13 GMT - . Launch Site: Wallops Island. Launch Complex: Wallops Island LA1. Launch Pad: LA1?. LV Family: Astrobee. Launch Vehicle: Astrobee F.

1972 December 6 - . 06:35 GMT - . Launch Site: Fort Churchill. LV Family: Astrobee. Launch Vehicle: Astrobee D. FAILURE: Failure.

- Auroral Quiet infrared Ionosphere / aeronomy mission - . Nation: USA. Agency: USAF CRL. Apogee: 27 km (16 mi).

1972 December 9 - . 01:30 GMT - . Launch Site: Fort Churchill. LV Family: Astrobee. Launch Vehicle: Astrobee D.

- Auroral Quiet infrared Ionosphere / aeronomy mission - . Nation: USA. Agency: USAF CRL. Apogee: 70 km (43 mi).

1973 March 21 - . 10:11 GMT - . Launch Site: Poker Flat. LV Family: Astrobee. Launch Vehicle: Astrobee D.

1973 April 6 - . 08:45 GMT - . Launch Site: Poker Flat. LV Family: Astrobee. Launch Vehicle: Astrobee D.

1973 June 30 - . 20:30 GMT - . Launch Site: Wallops Island. LV Family: Astrobee. Launch Vehicle: Astrobee D.

1973 October 3 - . 01:40 GMT - . Launch Site: White Sands. LV Family: Astrobee. Launch Vehicle: Astrobee D.

1973 October 3 - . 02:27 GMT - . Launch Site: White Sands. LV Family: Astrobee. Launch Vehicle: Astrobee D.

1973 October 3 - . 06:00 GMT - . Launch Site: White Sands. LV Family: Astrobee. Launch Vehicle: Astrobee D.

1974 February 8 - . 04:16 GMT - . Launch Site: Poker Flat. LV Family: Astrobee. Launch Vehicle: Astrobee D.

1974 April 11 - . 23:38 GMT - . Launch Site: Poker Flat. LV Family: Astrobee. Launch Vehicle: Astrobee D. FAILURE: Failure.

1974 April 12 - . 23:25 GMT - . Launch Site: Poker Flat. LV Family: Astrobee. Launch Vehicle: Astrobee D.

1974 May 8 - . Launch Site: White Sands. LV Family: Astrobee. Launch Vehicle: Astrobee F. FAILURE: Failure.

1974 October 10 - . 16:37 GMT - . Launch Site: White Sands. LV Family: Astrobee. Launch Vehicle: Astrobee D.

1975 February 26 - . 22:50 GMT - . Launch Site: Poker Flat. LV Family: Astrobee. Launch Vehicle: Astrobee D.

1975 March 1 - . 01:00 GMT - . Launch Site: Poker Flat. LV Family: Astrobee. Launch Vehicle: Astrobee D.

1975 May 15 - . 15:25 GMT - . Launch Site: White Sands. LV Family: Astrobee. Launch Vehicle: Astrobee F.

1975 July 15 - . 15:03 GMT - . Launch Site: White Sands. LV Family: Astrobee. Launch Vehicle: Astrobee D.

1975 October 14 - . 10:30 GMT - . Launch Site: White Sands. LV Family: Astrobee. Launch Vehicle: Astrobee F.

- Zodiacal infrared Infrared astronomy mission - . Nation: USA. Agency: USAF. Apogee: 265 km (164 mi).

1975 December 2 - . 12:57 GMT - . Launch Site: White Sands. LV Family: Astrobee. Launch Vehicle: Astrobee D.

- Twilight D-Region Aeronomy / technology mission - . Nation: USA. Agency: USAF CRL. Apogee: 120 km (70 mi).

1975 December 2 - . 13:50 GMT - . Launch Site: White Sands. LV Family: Astrobee. Launch Vehicle: Astrobee D.

- Twilight D-Region Aeronomy / technology mission - . Nation: USA. Agency: USAF CRL. Apogee: 124 km (77 mi).

1975 December 2 - . 17:00 GMT - . Launch Site: White Sands. LV Family: Astrobee. Launch Vehicle: Astrobee D.

- Twilight D-Region Aeronomy / technology mission - . Nation: USA. Agency: USAF CRL. Apogee: 125 km (77 mi).

1975 December 3 - . 00:35 GMT - . Launch Site: White Sands. LV Family: Astrobee. Launch Vehicle: Astrobee D.

- Twilight D-Region Aeronomy / technology mission - . Nation: USA. Agency: USAF CRL. Apogee: 125 km (77 mi).

1975 December 3 - . 00:59 GMT - . Launch Site: White Sands. LV Family: Astrobee. Launch Vehicle: Astrobee D.

- Twilight D-Region Aeronomy / technology mission - . Nation: USA. Agency: USAF CRL. Apogee: 125 km (77 mi).

1975 December 3 - . 02:00 GMT - . Launch Site: White Sands. LV Family: Astrobee. Launch Vehicle: Astrobee D.

- Twilight D-Region Aeronomy / technology mission - . Nation: USA. Agency: USAF CRL. Apogee: 127 km (78 mi).

1976 January 18 - . 19:28 GMT - . Launch Site: Wallops Island. LV Family: Astrobee. Launch Vehicle: Astrobee D.

1976 January 23 - . 19:32 GMT - . Launch Site: Wallops Island. LV Family: Astrobee. Launch Vehicle: Astrobee D.

1976 March 30 - . 16:50 GMT - . Launch Site: White Sands. LV Family: Astrobee. Launch Vehicle: Astrobee F.

1976 May 13 - . 02:51 GMT - . Launch Site: White Sands. LV Family: Astrobee. Launch Vehicle: Astrobee D.

1976 August 11 - . 15:45 GMT - . Launch Site: White Sands. LV Family: Astrobee. Launch Vehicle: Astrobee D.

1977 January 8 - . 19:38 GMT - . Launch Site: Wallops Island. LV Family: Astrobee. Launch Vehicle: Astrobee D.

1977 February 16 - . 03:00 GMT - . Launch Site: White Sands. LV Family: Astrobee. Launch Vehicle: Astrobee F.

1977 February 20 - . Launch Site: White Sands. LV Family: Astrobee. Launch Vehicle: Astrobee F.

1977 March 12 - . 03:30 GMT - . Launch Site: White Sands. LV Family: Astrobee. Launch Vehicle: Astrobee F.

1977 March 19 - . 06:06 GMT - . Launch Site: Fort Churchill. LV Family: Astrobee. Launch Vehicle: Astrobee F.

1977 July 21 - . 09:00 GMT - . Launch Site: White Sands. LV Family: Astrobee. Launch Vehicle: Astrobee F.

1977 July 27 - . 05:35 GMT - . Launch Site: White Sands. LV Family: Astrobee. Launch Vehicle: Astrobee F.

1977 September 29 - . 17:45 GMT - . Launch Site: White Sands. LV Family: Astrobee. Launch Vehicle: Astrobee F.

1977 December 11 - . 07:45 GMT - . Launch Site: White Sands. LV Family: Astrobee. Launch Vehicle: Astrobee F.

- UIT-Prototype F1 Ultraviolet astronomy mission - . Nation: USA. Agency: NASA. Apogee: 226 km (140 mi).

1978 January 9 - . 20:00 GMT - . Launch Site: White Sands. LV Family: Astrobee. Launch Vehicle: Astrobee F.

1978 January 10 - . 06:15 GMT - . Launch Site: White Sands. LV Family: Astrobee. Launch Vehicle: Astrobee F.

1978 January 21 - . 09:01 GMT - . Launch Site: White Sands. LV Family: Astrobee. Launch Vehicle: Astrobee F.

1978 March 8 - . 04:00 GMT - . Launch Site: White Sands. LV Family: Astrobee. Launch Vehicle: Astrobee F.

1978 March 13 - . 07:50 GMT - . Launch Site: Fort Churchill. LV Family: Astrobee. Launch Vehicle: Astrobee F.

1978 May 15 - . 09:05 GMT - . Launch Site: White Sands. LV Family: Astrobee. Launch Vehicle: Astrobee F.

- NRL Mk II ultraviolet Camera Ultraviolet astronomy mission - . Nation: USA. Agency: NASA. Apogee: 211 km (131 mi).

1978 July 20 - . 04:30 GMT - . Launch Site: White Sands. LV Family: Astrobee. Launch Vehicle: Astrobee F.

1978 September 20 - . 02:58 GMT - . Launch Site: White Sands. LV Family: Astrobee. Launch Vehicle: Astrobee F.

1978 September 26 - . 05:05 GMT - . Launch Site: White Sands. LV Family: Astrobee. Launch Vehicle: Astrobee F.

1978 December 1 - . 07:20 GMT - . Launch Site: White Sands. LV Family: Astrobee. Launch Vehicle: Astrobee F.

- JHU UVT F9 (Jupiter) Ultraviolet astronomy mission - . Nation: USA. Agency: NASA. Apogee: 238 km (147 mi).

1978 December 11 - . 03:00 GMT - . Launch Site: White Sands. LV Family: Astrobee. Launch Vehicle: Astrobee F.

1979 January 9 - . 11:53 GMT - . Launch Site: White Sands. LV Family: Astrobee. Launch Vehicle: Astrobee F.

1979 January 17 - . 20:00 GMT - . Launch Site: White Sands. LV Family: Astrobee. Launch Vehicle: Astrobee F.

1979 January 28 - . 03:07 GMT - . Launch Site: Fort Churchill. LV Family: Astrobee. Launch Vehicle: Astrobee F. FAILURE: Failure.

1979 February 20 - . Launch Site: Fort Churchill. LV Family: Astrobee. Launch Vehicle: Astrobee D.

1979 February 26 - . 16:50 GMT - . Launch Site: Red Lake. Launch Complex: Red Lake MCM. LV Family: Astrobee. Launch Vehicle: Astrobee D.

1979 February 27 - . 12:00 GMT - . Launch Site: Red Lake. Launch Complex: Red Lake MCM. LV Family: Astrobee. Launch Vehicle: Astrobee D.

1979 March 15 - . 05:20 GMT - . Launch Site: White Sands. LV Family: Astrobee. Launch Vehicle: Astrobee F.

1979 March 21 - . 03:45 GMT - . Launch Site: White Sands. LV Family: Astrobee. Launch Vehicle: Astrobee F.

1979 May 21 - . 05:00 GMT - . Launch Site: White Sands. LV Family: Astrobee. Launch Vehicle: Astrobee F.

1979 May 21 - . 06:40 GMT - . Launch Site: White Sands. LV Family: Astrobee. Launch Vehicle: Astrobee F.

1979 June 2 - . Launch Site: White Sands. LV Family: Astrobee. Launch Vehicle: Astrobee F.

- NRL far ultraviolet Spectrograph Ultraviolet astronomy mission - . Nation: USA. Agency: NASA. Apogee: 200 km (120 mi).

1979 June 7 - . Launch Site: Wallops Island. LV Family: Astrobee. Launch Vehicle: Astrobee D.

1979 August 3 - . 09:20 GMT - . Launch Site: White Sands. LV Family: Astrobee. Launch Vehicle: Astrobee F.

- FWIR III Aeronomy / infrared astronomy mission - . Nation: USA. Agency: USAF GL. Apogee: 172 km (106 mi).

1979 August 17 - . 21:15 GMT - . Launch Site: White Sands. LV Family: Astrobee. Launch Vehicle: Astrobee F.

1979 September 16 - . Launch Site: Wallops Island. LV Family: Astrobee. Launch Vehicle: Astrobee D.

1979 September 20 - . Launch Site: Wallops Island. LV Family: Astrobee. Launch Vehicle: Astrobee D.

1979 September 24 - . 11:15 GMT - . Launch Site: White Sands. LV Family: Astrobee. Launch Vehicle: Astrobee F.

1979 October 1 - . Launch Site: Wallops Island. LV Family: Astrobee. Launch Vehicle: Astrobee D.

1979 October 23 - . 03:15 GMT - . Launch Site: White Sands. LV Family: Astrobee. Launch Vehicle: Astrobee F.

1979 December 14 - . Launch Site: White Sands. LV Family: Astrobee. Launch Vehicle: Astrobee F.

1979 December 18 - . Launch Site: Wallops Island. LV Family: Astrobee. Launch Vehicle: Astrobee D.

1980 January 21 - . 08:05 GMT - . Launch Site: White Sands. LV Family: Astrobee. Launch Vehicle: Astrobee F.

1980 February 16 - . 08:25 GMT - . Launch Site: San Marco. LV Family: Astrobee. Launch Vehicle: Astrobee D.

1980 February 16 - . 20:30 GMT - . Launch Site: San Marco. LV Family: Astrobee. Launch Vehicle: Astrobee D.

1980 March 22 - . 10:30 GMT - . Launch Site: White Sands. LV Family: Astrobee. Launch Vehicle: Astrobee F.

1980 March 28 - . 06:26 GMT - . Launch Site: Fort Churchill. LV Family: Astrobee. Launch Vehicle: Astrobee F.

1980 May 22 - . 15:00 GMT - . Launch Site: White Sands. LV Family: Astrobee. Launch Vehicle: Astrobee F.

1980 June 16 - . 08:00 GMT - . Launch Site: White Sands. LV Family: Astrobee. Launch Vehicle: Astrobee F.

- NRL far ultraviolet Spectrograph Ultraviolet astronomy mission - . Nation: USA. Agency: NASA. Apogee: 217 km (134 mi).

1980 June 27 - . 19:01 GMT - . Launch Site: White Sands. LV Family: Astrobee. Launch Vehicle: Astrobee F.

1980 August 9 - . 07:30 GMT - . Launch Site: White Sands. LV Family: Astrobee. Launch Vehicle: Astrobee F.

1980 November 1 - . 06:44 GMT - . Launch Site: White Sands. LV Family: Astrobee. Launch Vehicle: Astrobee F.

1981 January 20 - . 04:50 GMT - . Launch Site: White Sands. LV Family: Astrobee. Launch Vehicle: Astrobee F.

- NRL far ultraviolet Spectrograph Ultraviolet astronomy mission - . Nation: USA. Agency: NASA. Apogee: 209 km (129 mi).

1981 January 29 - . 04:12 GMT - . Launch Site: Fort Churchill. LV Family: Astrobee. Launch Vehicle: Astrobee F.

1981 October 17 - . Launch Site: White Sands. LV Family: Astrobee. Launch Vehicle: Astrobee F.

1983 March 2 - . 02:17 GMT - . Launch Site: White Sands. LV Family: Astrobee. Launch Vehicle: Astrobee F.

Back to top of page

Home - Search - Browse - Alphabetic Index: 0- 1- 2- 3- 4- 5- 6- 7- 8- 9

A- B- C- D- E- F- G- H- I- J- K- L- M- N- O- P- Q- R- S- T- U- V- W- X- Y- Z

© 1997-2019 Mark Wade - Contact

© / Conditions for Use