Home - Search - Browse - Alphabetic Index: 0- 1- 2- 3- 4- 5- 6- 7- 8- 9

A- B- C- D- E- F- G- H- I- J- K- L- M- N- O- P- Q- R- S- T- U- V- W- X- Y- Z

Saturn A-1

Saturn A-1 Credit: © Mark Wade |

Status: Study 1959. Payload: 6,500 kg (14,300 lb). Thrust: 6,690.00 kN (1,503,970 lbf). Gross mass: 532,280 kg (1,173,470 lb). Height: 60.00 m (196.00 ft). Diameter: 6.52 m (21.39 ft). Apogee: 185 km (114 mi).

The life and death of the A-1 version, which would have provided the United States with a heavy-lift launch vehicle earlier than any other alternative, is related by Medaris, commander of the ABMA, in his autobiography:

We had gone through the whole process of selecting upper stages and had made our recommendations to ARPA. We had indicated very clearly that we were willing to accept either the Atlas or Titan as the basis for building the second stage. The real difference was that in one case we would be using the Atlas engines and associated equipment, built by North American, while in the other case, we would be using the Titan power plant built by Aerojet. Largely because of the multitude of different projects that had been saddled on the Atlas, we favor the Titan. Convair builds the Atlas, and we had great confidence in Convair's engineering, but this was over shadowed in our mind by the practical difficulties of getting enough Atlas hardware. However, we assured ARPA that we would take either one.In the event, neither the Saturn A-1 or the Titan C went ahead. After several twists and turns, the Saturn I with the 160-inch upper stage was developed, the second production lot even being configured for Dynasoar. However Dynasoar was finally slated to fly on the Titan 3C, a third alternative in the USAF SLV-4 competition of 1961. Dynasoar in turn was cancelled, and the Saturn I was superseded by the Saturn IB for manned earth-orbit Apollo flights. Only the Titan 3C and its descendants would soldier on into the 21st Century, as the heavy-lift mainstay of American expendable boosters.The time scale was important. In order to get an operational vehicle in the air as soon as possible, and be able to match and possibly exceed Russia's capabilities, we recommended that the first flying vehicle to be made up of Saturn as the first stage and a second stage built with a Titan power plant. We also recommended using the tooling available at Martin for the airframe. We felt that by the time we got through the second-stage tests, the powerful new Centaur oxygen-hydrogen engine would be in good enough shape to become the third stage. We then calculated that a, year afterwards, or perhaps a little later, could begin to come up with a second-generation satellite vehicle that would cluster the Centaur engine for second stage.

Our people made extensive presentations to ARPA and NASA during the late spring of 1959, always taking the position that we could work with either combination that was agreed to by both. We were anxious to have them agree, because it seemed obvious to us that the nation could not afford more than one very large booster project. We believed that the resulting vehicle would be enormously useful both to the Defense Department for advanced defense requirements, and NASA for its scientific and civilian exploration of space.

We finally got a decision. - - We were told that we could begin designing the complete vehicle along the lines that we had recommended, namely, with the Titan as the basis for the second stage. So far there was no sign of trouble. Remembering the difficulties that we had had in connection with our requirements for North American engines for Jupiter, with the North American people largely under control of the Air Force, we knew that if we were to get on with the job properly we had to make our contract direct with Martin for the second stage work, and with the Convair/Pratt & Whitney group for the adaptation of Centaur to the third stage. We asked the Air Force for clearance to negotiate these matters with the companies concerned The Air Force (BMD) refused, and insisted that we let them handle all areas with the contractor. They used the old argument that they as a group could handle the responsibility much better, and that if they didn't handle it, there were bound to be priority problems connected with the military programs for Titan and others. We knew that the Air Force had no technical capacity of their own to put into this project, and that if we gave them the whole job, they would be forced to use the Ramo-Wooldridge organization, now known as the Space Technology Laboratories, as their contract agent to exercise technical supervision and co-ordination. While we knew and respected a few good men in STL, we felt we had ample cause to lack confidence in the organization as such. As a matter of fact, when the House Committee on Government Operations looked askance at STL with respect to their position as a profit-making organization, some of the best men had left the organization. We threw this one out on the table and said that we would not, under any circumstances, tolerate the interference of STL in this project. We knew that we had all the technical capability that was needed to supervise the overall system, and could not stand the delays and arguments that would most assuredly result were that organization to be thrown in also. Both sides presented their arguments to ARPA...Mr. Roy Johnson ruled that we could go ahead and contract directly Martin and others as required. It is understandable that the Air Force took this decision with poor grace. It represented a major setback to the system of absolute control over their own contractors, no matter for whom those contractors happened to be doing work. It also left them pretty much on the side- lines with respect to major participation in or control over any portion of the Saturn as a space vehicle.

With the amount of money still available to us from fiscal year 1960 and with our authorization from ARPA, we proceeded immediately to negotiate engineering contracts with Martin. We thought that since Mr. Johnson had complete control over this program, we had gotten over the last important hurdle and could get on about our business. Little did we realize the hornet's nest that had been stirred up, and less did we realize that winning that battle was finally to mean that we would lose the war, and would lose von Braun's entire organization.

We had only a few weeks of peace and quiet. From events that occurred later, I think I can make a fair estimate of what happened during this short period. Having been overruled by Johnson, the Air Force took a new approach. They decided that in view of the importance and power that was given the Deputy Secretary of Defense for Research and Engineering by the 1958 changes in the defense organization, Dr. York represented their best avenue of approach through which to get back in the war.

For reasons of economy we had recommended, and it had been approved, that in building the second stage, we would use the same diameter as the Titan first stage -- 120 inches. The major costs of tooling for the fabrication of missile tanks and main structure is related to the diameter. Changes in length cost little or nothing in tooling. How the tanks are divided internally, or the structure reinforced inside, or the kind of structural detail that is used at the end in order to attach the structure to a big booster below, or to a different size stage above, have very little effect on tooling problems. However, a change in diameter sets up a major question of tools, costs, and time.

Suddenly, out of the blue came a directive to suspend work on the second stage, and a request for a whole new series of cost and time estimates, including consideration of increasing the second stage diameter to 160 inches. It appeared that Dr. York had entered the scene, and had pointed up the future requirements of Dynasoar as being incompatible with the 120-inch diameter. He had posed the question of whether it was possible for the Saturn to be so designed as to permit it to be the booster for that Air Force project.

We were shocked and stunned. This was no new problem, and we could find no reason why it should not have been considered, if necessary, during the time that the Department of Defense and NASA were debating the whole question of what kind of upper stages we should use. Nevertheless, we very speedily went about the job of estimating the project on the basis of accepting the 160-inch diameter. At the same time it was requested that we submit quotations for a complete operational program to boost the Dynasoar for a given number of flights. As usual, we were given two or three numbers, rather than one fixed quantity, and asked to estimate on each of them.

By this time, my nose was beginning to sniff a strange odor of "fish." I put my bird dogs to work to try to find out what was going on and with whom we had to compete. We discovered that the Air Force had proposed a wholly different and entirely new vehicle as the booster for Dynasoar, using a cluster of Titan engines and upgrading their performance to get the necessary first-stage thrust for take-off. This creature was variously christened the Super Titan, or the Titan C. No work had been done on this vehicle other than a hasty engineering outline. Yet the claim was made that the vehicle in a two-stage or three-stage configuration could be flown more quickly than the Saturn, on which we had already been working hard for many months. Dates and estimates were attached to that proposal which at best ignored many factors of costs, and at worst were strictly propaganda.

LEO Payload: 6,500 kg (14,300 lb) to a 185 km orbit at 28.00 degrees. Flyaway Unit Cost 1985$: 73.800 million.

Stage Data - Saturn A-1

- Stage 1. 1 x Saturn I. Gross Mass: 432,681 kg (953,898 lb). Empty Mass: 45,267 kg (99,796 lb). Thrust (vac): 7,582.100 kN (1,704,524 lbf). Isp: 289 sec. Burn time: 150 sec. Isp(sl): 255 sec. Diameter: 6.52 m (21.39 ft). Span: 6.52 m (21.39 ft). Length: 24.48 m (80.31 ft). Propellants: Lox/Kerosene. No Engines: 8. Engine: H-1. Status: Out of Production.

- Stage 2. 1 x Titan 1-1. Gross Mass: 76,203 kg (167,998 lb). Empty Mass: 4,000 kg (8,800 lb). Thrust (vac): 1,467.908 kN (329,999 lbf). Isp: 290 sec. Burn time: 138 sec. Isp(sl): 256 sec. Diameter: 3.05 m (10.00 ft). Span: 3.05 m (10.00 ft). Length: 16.00 m (52.00 ft). Propellants: Lox/Kerosene. No Engines: 2. Engine: LR-87-3. Status: Out of Production.

- Stage 3. 1 x Centaur C. Gross Mass: 15,600 kg (34,300 lb). Empty Mass: 1,996 kg (4,400 lb). Thrust (vac): 133.448 kN (30,000 lbf). Isp: 425 sec. Burn time: 430 sec. Diameter: 3.05 m (10.00 ft). Span: 3.05 m (10.00 ft). Length: 9.14 m (29.98 ft). Propellants: Lox/LH2. No Engines: 2. Engine: RL-10A-1. Status: Out of Production.

Family: orbital launch vehicle. People: von Braun. Country: USA. Engines: LR87-3, H-1 engine, RL-10A-1. Stages: Titan 1-1, Centaur C, S-I stage.

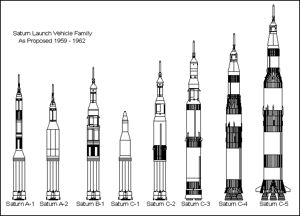

| Saturn A-1 to C-5 Credit: © Mark Wade |

1959 April 15 - . LV Family: Saturn I. Launch Vehicle: Saturn A-1.

- Use of Titan for Saturn upper stages - .

Nation: USA.

Program: Apollo.

In response to a request by the DOD-NASA) Saturn Ad Hoc Committee, the Army Ordnance Missile Command (AOMC) sent a supplement to the "Saturn System Study" to the Advanced Research Projects Agency ARPA describing the use of Titan for Saturn upper stages. Additional Details: here....

Back to top of page

Home - Search - Browse - Alphabetic Index: 0- 1- 2- 3- 4- 5- 6- 7- 8- 9

A- B- C- D- E- F- G- H- I- J- K- L- M- N- O- P- Q- R- S- T- U- V- W- X- Y- Z

© 1997-2019 Mark Wade - Contact

© / Conditions for Use