Home - Search - Browse - Alphabetic Index: 0- 1- 2- 3- 4- 5- 6- 7- 8- 9

A- B- C- D- E- F- G- H- I- J- K- L- M- N- O- P- Q- R- S- T- U- V- W- X- Y- Z

MOBEV R1CB

MOBEV R1CB

Status: Study 1966. Gross mass: 4,539 kg (10,006 lb).

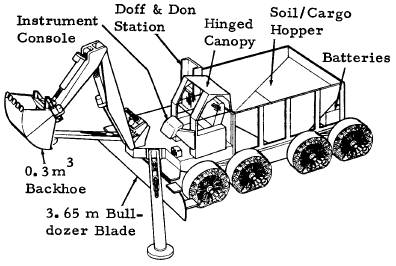

To obtain maximum draw bar pull, approximately 1800 kg of ballast (lunar soil) had to be placed in the vehicle hopper. When the ballast was no longer required, or if the vehicle was used for earth moving, doors in the bottom of the hopper could be opened, providing variable flow dumping capability. The available energy permitted bulldozing or backhoeing during the entire sortie duration. The R1CB had an average no-load speed of 2.5 km/hr. The crew station provided on this vehicle consisted of a seat, restraints, and an open cabin with a protective windshield. The cabin/windshield pivoted upwards to permit astronaut entry. The power subsystem consisted of rechargeable AgCd batteries, with a total available energy per charge of 24 kWh. Recharge was from a shelter or other external source. The mobility subsystem consisted of four pairs of metal-elastic wheels, each pair mounted on a bogie. Each of the eight wheels was individually powered by a motor and transmission. Steering was accomplished by varying motor rpm to allow scuff steering. The vehicle appendages include a bulldozing blade, backhoe, trailer hitch, stabilization outriggers, and power winch. The bulldozing blade had a capacity of approximately 1.1 cu m, with a blade penetration of 0.25 m. Blade pitch angle and height control was accomplished by electrical linear actuators. The backhoe consisted of a boom, dipper stick, and a 0.3 cu m bucket. The bucket could be used in a digging mode or clam shell mode, and had a maximum digging depth of 4.25 m.

The R1CB was designed to tow the R0BB Prime Mover/Trailer. The ROBB trailer concept provided base support capability in terms of cargo transportation within close proximity to the base. This trailer was a derivative of the R2C(1)E exploration vehicle design, and consisted of only the R2C(1)E mobility subsystem minus the power steering equipment. Structural stiffeners and a flat bed deck were added to the modified mobility subsystem to provide the cargo-carrying capability. A tow bar was also added which provided steering by means of mechanical linkages. Power for the individual wheel drive motors was provided by the prime mover subsystem by means of a cable.

Crew Size: 1. Electric System: 4.00 average kW.

Family: Lunar Rovers, Moon. Country: USA. Agency: NASA, Bendix.

Back to top of page

Home - Search - Browse - Alphabetic Index: 0- 1- 2- 3- 4- 5- 6- 7- 8- 9

A- B- C- D- E- F- G- H- I- J- K- L- M- N- O- P- Q- R- S- T- U- V- W- X- Y- Z

© 1997-2019 Mark Wade - Contact

© / Conditions for Use