Home - Search - Browse - Alphabetic Index: 0- 1- 2- 3- 4- 5- 6- 7- 8- 9

A- B- C- D- E- F- G- H- I- J- K- L- M- N- O- P- Q- R- S- T- U- V- W- X- Y- Z

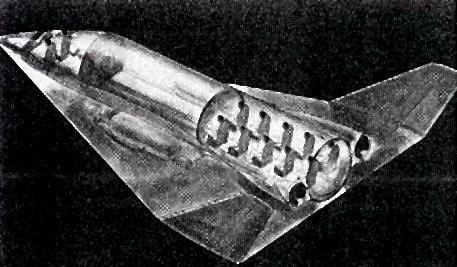

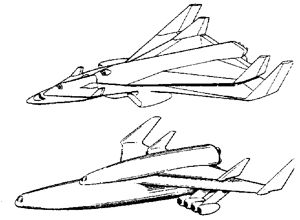

Recoverable Booster Systems for Orbital Logistics

Recoverable Booster

Recoverable Booster Systems for Orbital Logistics

Credit: NASA

Status: Study 1963.

System I appeared to be uneconomical as a high-volume manned transportation system even if the crew capsule could be reused 10 times. Lockheed's preferred System II would have retained the Saturn IB booster but replaced the Apollo with a new reusable DynaSoar-like10-man spaceplane that could be reused 500 times.

The fully reusable options were horizontal takeoff / horizontal landing two-stage-to-orbit designs launched from a ground accelerator sled. The System III booster was rocket-powered while the System IV booster used in-flight liquid oxygen collection and ramjet propulsion. The third stage spaceplane from System II was standard for the reusable systems as well. After deploying the third stage the reusable vehicles would fly orbit-once-around missions before returning to the launch base.

The System III and IV requirements were as follows:

- 95% mission reliability (0.1% vehicle attrition rate).

- 2950 kg payload and 10 passenger capability.

- 7.5 day minimum turnaround between missions (11-23 days nominal).

- Mission life of 500 flights.

- Flight rates of 100-300 missions per year in 1973-80.

The estimated operating cost for the reusable systems ranged between $ 6.8 million per mission at a flight rate of 50 flights per year to $1.275 million at 400 flights per year in FY 1964 dollars. System III and System IV appeared to be equally cost competitive, but the development cost and risk would be lower for the all-rocket booster concept.

Masses:

- Stage 1: System III booster (161.750 metric tons dry / 646.823 metric tons gross) / System IV booster (113.4 metric tons dry / 217.724metric tons gross).

- Stage 2 orbiter (common to System III / System IV): (33.475 metric tons dry / 167.376 metric tons gross). Orbiter would perform "orbit once around" after deploying third stage

- Stage 3: (common to Systems II, III, IV): Dyna Soar type mini-shuttle (7166 kg empty / 12700 kg gross).

Launch Price $: 6.800 million in 1963 dollars.

Family: orbital launch vehicle, Sled-Launched, Winged. Country: USA. Spacecraft: Lockheed Space Taxi. Agency: Lockheed. Bibliography: 521.

| Recoverable Booster Recoverable Booster Systems for Orbital Logistics Credit: NASA |

Back to top of page

Home - Search - Browse - Alphabetic Index: 0- 1- 2- 3- 4- 5- 6- 7- 8- 9

A- B- C- D- E- F- G- H- I- J- K- L- M- N- O- P- Q- R- S- T- U- V- W- X- Y- Z

© 1997-2019 Mark Wade - Contact

© / Conditions for Use