Home - Search - Browse - Alphabetic Index: 0- 1- 2- 3- 4- 5- 6- 7- 8- 9

A- B- C- D- E- F- G- H- I- J- K- L- M- N- O- P- Q- R- S- T- U- V- W- X- Y- Z

Lunox

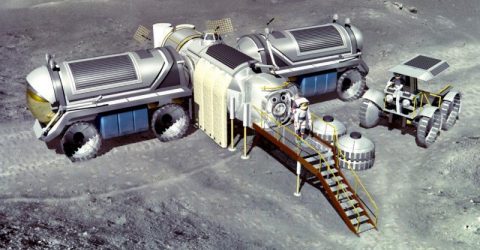

Lunox

Credit: NASA

Status: Study 1993.

This allowed smaller launch and space vehicles, and reduced costs by 33% to 50%. The study marked the end of a brief NASA obsession with extreme heavy lift launch vehicles. But it was also eclipsed by Mars Semi-Direct plans that left out any intermediate lunar bases, and actual work on the International Space Station.

The NASA/JSC LUNOX proposal from 1993 tried to reduce the cost of maintaining a "First Lunar Outpost" by producing liquid oxygen propellant for the return to Earth from lunar soil (the lighter hydrogen fuel was brought from Earth since it was not readily available on the Moon). Similar in-situ resource utilization schemes had been proposed for large moon bases, but LUNOX tried to use the same strategy to reduce the cost of pioneering small-scale manned lunar exploration as well. This technique would permit drastic downsizing of the manned space vehicles and cost reductions of up to 50%. The number of launches would also be reduced, despite utilizing smaller Shuttle-derived rockets instead of Saturn V-class rockets.

The unmanned Phoenix/LUNOX lander would carry a lunar oxygen production plant/storage facility and a nuclear power reactor to the moon's surface. The total mass of this "package" was 12,454 kilograms. The mass summary was as follows:

- Phoenix Unmanned Lander: 4,717 kg dry, 16,578 kg propellants

- Cargo: 12,454 kg

- Translunar Injection Stage: 6,130 kg dry, 43,930 kg propellants Total Mass In Low Earth Orbit 83,809 kg

A second unmanned lander would deliver six small robotic lunar vehicles, after the LUNOX plant and reactor had been deployed. Two "Loader" bulldozers would collect and sort ~500kg/hour of ilmenite-rich lunar soil, which would be fed into the LUNOX plant and processed into liquid oxygen propellant. The process was based on H2 reduction of lunar regolith in a fluidized-bed reactor, solid-state high-temperature electrolysis and Stirling-cycle O2 liquefaction and refrigeration. Two "Tankers" transported the liquid oxygen from the LUNOX factory to other users on the lunar surface ( the annual production capability was 24 000kg, assuming an extraction efficiency of 4% after benefaction). Finally, two "Haulers" were available for moving heavy equipment across short distances. All rovers use regenerative power sources which were recharged from the nuclear reactor surface power supply.

The third and fourth cargo landers would deliver 2000 kg of science experiments, two Mobile Power Unit (MPU) trailers and two 2-man long range rovers to the lunar outpost. These vehicles were very similar to Eagle Engineering's "MOSAP" concept from 1988. They would provide power, communications, thermal control, life support and habitation for 14 days on the lunar surface. The minimum exploration range was several hundred kilometers. Each rover obtained mobile power and water for the life support system on long journeys from the MPU "power cart" trailers, which contained fuel cells. These cells produced water and electrical power by combining lunar oxygen and hydrogen brought from Earth.

The lunar outpost crew of four astronauts would live in the pressurized rovers. The vehicles would receive auxiliary power, life support and other services from a large support module on wheels, which was delivered on the fifth cargo flight. The support module contained "docking ports" for two rovers and an airlock. It also provided additional habitable volume and space suit maintenance facilities. The life support system did not recycle waste water due to size and weight restrictions. Water was produced by auxiliary fuel cells, which used oxygen produced by the LUNOX system and hydrogen imported from Earth.

Lunar Outpost Elements Mass Summary

- Flight 1

- Lunox Plant: 7,269 kg

- Nuclear Reactor (40-60kwe): 5,110 kg

- Flight 2

- Tanker #1: 1,471 kg

- Tanker #2: 1,471 kg

- Loader #1: 1,728 kg

- Loader #2: 1,728 kg

- Hauler #1: 962 kg

- Hauler #2: 962 kg

- Flight 3

- Pressurized Rover #1: 5,150 kg

- Mobile Power Unit #1: 1,544 kg

- Science Payload: 1,000 kg

- Flight 4

- Pressurized Rover #2: 5,150 kg

- Mobile Power Unit #2: 1,544 kg

- Science Payload: 1,000

- Flight 5: Airlock/Node Support Vehicle: 11,010 kg

- Flight 6: Logistics And Spares: 12,454 kg

- Total: 59,553 kg

- Apollo type Crew Module: 5935 kg dry; 199 kg propellants

- Crew and Support: 609 kg

- Phoenix Manned Lander (4 X 31 150kn Thrust Engines; 4:1 Throttling): 5505 kg dry; 16944 kg propellants

- Cargo: 2000 kg

- Lh2 Fuel for Return Trip: 2492 kg

- Translunar Injection Stage (3 X Rl-10-A4 Engines; 449s Isp): 6,130 kg dry; 43,930 kg propellants

- Total Mass in Low Earth Orbit: 83,744 kg dry

- Lunar Oxygen Required: 10,165 kg

Like NASA's "First Lunar Outpost" study, LUNOX would only employ expendable spacecraft and rockets although the lunar surface infrastructure was reused. The first mission would deliver enough consumables for a 2-crew, 14-day mission to accomplish setup, repair or maintenance of the surface infrastructure. Future 4-crew missions of up to 45 days would also be feasible, although the required supplies (crew consumables, experiments, liquid hydrogen for the LUNOX system and fuel cells) would have to be delivered by a separate unmanned cargo flight.

The final "Phase II" configuration would include the two pressurized rovers attached to the supporting node module. Normally, the rovers obtained their power from the LUNOX reactor which was connected to the node. When not attached to the lunar outpost, the rovers could venture hundreds of kilometers from the landing site, enabling a comprehensive survey of the lunar surface. One rover could house all four astronauts in an emergency as a safeguard against catastrophic failure. Without the Mobile Power Unit the rover would only be capable of 2-3 day missions. After 45 days of exploring the Moon, the astronauts refuel their landing craft with 10,165 kg of lunar oxygen. Rovers would deliver the propellant while a Mobile Power Unit provided "stay alive" electric power to the lander.

The LUNOX plan assumed a first manned landing in 2005. The total cost was estimated at $19.6 billion in FY 1993 dollars -- $22.5B at 1999 economic conditions. The cost of developing lunar oxygen mining equipment would be relatively high, but the required technologies -- automation, robotics, lunar surface vehicles, in-situ resource utilization -- could have considerable relevance to the American commercial sector. The Shuttle-derived heavy lift vehicle and Phoenix lander would be less costly to develop thanks to the LUNOX infrastructure. Each manned lunar landing would cost $1.7 billion (including $550 million for the launcher) and the unmanned landings would cost $1 billion each. In comparison, the 1992 First Lunar Outpost baseline launch vehicle and spacecraft would have cost $4.6 billion and $3.7 billion, respectively. LUNOX would have some built-in redundancy even if the cost-reducing elements of the plan (Energia, lunar oxygen mining) prove unworkable. All cargo elements could be launched on American rockets in case the Russians pull out of the project. Oxygen for the return trip could also be brought from Earth in an emergency, although doing so would increase the launch cost by 50%. LUNOX cost summary was as follows: ($ billion,1999)

Development Cost

- Lunox Systems: $3.9

- Lunar Surface Systems: $4.6

- Science Payloads: $0.9

- Manned Phoenix Development: $3.5

- Cargo Spacecraft Development: $0.0

- Launch Vehicle Development: $1.2

- Total Development Cost: $14.1

Production Cost

- Launch Vehicle Production (X7): $4.0

- Manned Phoenix Production (X1): $1.2

- Cargo Spacecraft Production (X6): $3.2

- Total Production Cost: $8.4

Article by Marcus Lindroos

Family: Lunar Bases, Moon. Country: USA. Agency: NASA Houston.

| Lunox Credit: NASA |

| Lunox Credit: NASA |

Back to top of page

Home - Search - Browse - Alphabetic Index: 0- 1- 2- 3- 4- 5- 6- 7- 8- 9

A- B- C- D- E- F- G- H- I- J- K- L- M- N- O- P- Q- R- S- T- U- V- W- X- Y- Z

© 1997-2019 Mark Wade - Contact

© / Conditions for Use