Home - Search - Browse - Alphabetic Index: 0- 1- 2- 3- 4- 5- 6- 7- 8- 9

A- B- C- D- E- F- G- H- I- J- K- L- M- N- O- P- Q- R- S- T- U- V- W- X- Y- Z

Bio-Suit

Biosuit |

Status: Design 2001.

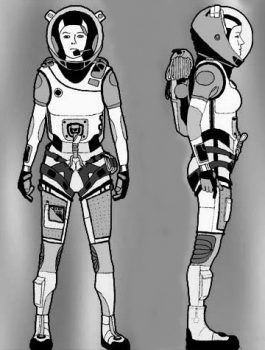

The Bio-Suit was a novel approach to spacesuit design that used and biomedical breakthroughs in skin replacement and materials to replace the bulky conventional "balloon" spacesuit with a 'second skin' approach to provide light weight, flexibility, and comfort in all extraterrestrial environments. It provided life support through use of mechanical counterpressure applied to the entire body through a tight-fitting suit, excepting a helmet for the head. The inner layer of the Bio-Suit could be sprayed on, and disposed of, together with dirt and dust, after each EVA. The external layers would include embedded "wearable technologies" that would be tailored to the environment and mission.

Existing space suits used hard fiberglass or metal and soft fabric components. Mobility was obtained by pleats that opened as joints bent and rotational bearings. These suits, all derived from the very fist purpose-designed spacesuits of the 1960's, were heavy, bulky, restricted astronaut mobility, and required extensive special training and exhausting joint torque force to work in. A modern Mechanical Counter Pressure (MCP) suit, first studied by NASA in 1971 as the Space Activity Suit, would eliminate these difficulties. The Bio-Suit study did not identify a specific design, but rather identified candidate technologies for the suit layers and the embedded information systems. These included:

- Electric Alloy Mesh Concept, using a seamless Shape Memory Alloy mesh to generate voltage-controlled mechanical counter-pressure. Pressure would be distributed by a viscous thermal-regulating gel layer. The gel layer moderated the high temperature of the SMA later and protected the body against impacts the skin directly, wicking away perspiration and absorbing body heat.

- Thermal Gel Suit Concept, using "smart" polymer gels which expanded at a threshold temperature to create mechanical counter-pressure. The smart gel was trapped in a quilted layer beneath a stretchless restraint layer. The restraint layer prevented outward expansion of the gel, directing the pressure inwards against the body.

- Electric Gel Suit , using "smart polymer gels which expanded in an electric field to create mechanical counter-pressure. The smart gel was trapped in a quilted layer, between metallized fabric layers, beneath a stretchless restraint layer. Opposite charges applied to the metallized layers produced a small electric field sufficient to stimulated the expanding smart gel.

- Stretch Alloy Band Suit Concept using the super elastic properties of Shape Memory Alloys (SMA) to allow the suit's volume to expand enough for donning. Charge would then applied to the SMA band which pulled together the seam of a uni-directional stretch fabric layer, which was able to stretch longitudinally in order to allow flexion at the joints.

- Electric Alloy Zipper Suits using shape memory alloy strips to aid and control the application of mechanical counter pressure while manually zipping together seams in a uni-directional stretch fabric layer.

- Electric Alloy Remote Zipper Suit concept, as the previous concept, but instead of being zipped manually, tightened all at once by digital controls at the shoulders. This system assured uniformity of mechanical counter-pressure and ease of operation.

- Absorb concept, which would collect perspiration in a removable component within the suit, either a highly absorptive fabric layer similar to long underwear, or desiccant packs at critical locations.

- Vent-to-Atmosphere concept, which controlled perspiration by venting moisture directly to the outside environment. A selective, semi-permeable organic layer closest to the skin allowed perspiration to pass through at a moderate rate. Subsequent layers of the suit, including the mechanical counter-pressure layer, were also semi-permeable. The openings in the membranes were large enough to allow the suit to breath, but small enough to prevent unwanted fluid loss.

- Transport concept, using a layer of tiny tubes to channel perspiration away from the body to a remote collection point. These tubes might be manufactured or perhaps organic such as the aquaporin network in plant membranes. A partial vacuum at the collection end might moved perspiration through the tubes, or perhaps work would be done by tiny piezoelectric pumps powered by energy harvested from body motion.

Family: Space Suits. Country: USA. Agency: MIT. Bibliography: 4470, 6391.

Back to top of page

Home - Search - Browse - Alphabetic Index: 0- 1- 2- 3- 4- 5- 6- 7- 8- 9

A- B- C- D- E- F- G- H- I- J- K- L- M- N- O- P- Q- R- S- T- U- V- W- X- Y- Z

© 1997-2019 Mark Wade - Contact

© / Conditions for Use